|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

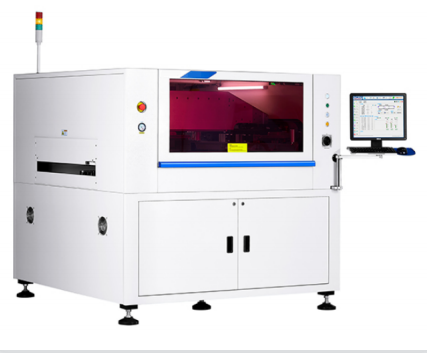

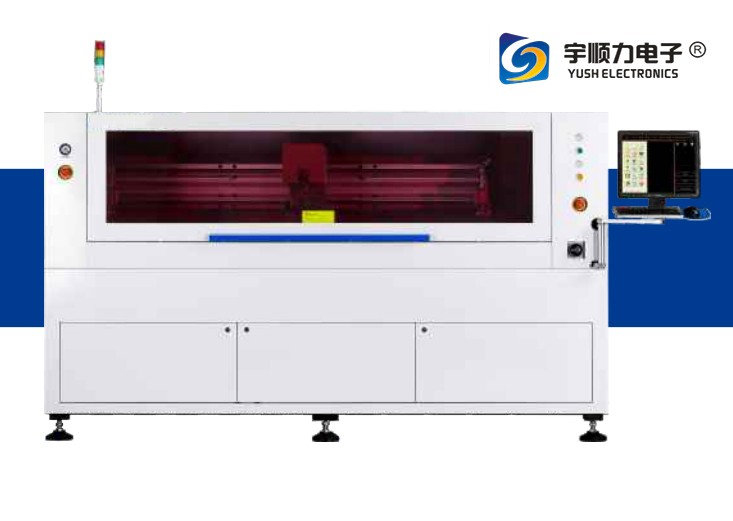

| Full Auto Stencil Printing Machine | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description:

Features 1. Auto balance the squeegee pressure which is adjustable 2.Intelligent 2D detection 3.Dry and wet cleaning.Option:vacuumcleaning 4.Option: for thin board printing 5.Advanced mark point recognition technology and stable system capability 6.The first online calibration technology in China

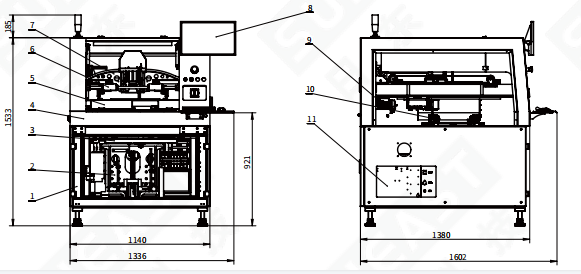

Overall diagram 1.Rack module 2.Lifting module 3.Platform alignment module 4.Housing module 5.Image capture module 6.Stencil frame positioning module 7.Squeegee module 8.Display module 9.Cleaning module 10.Conveyor module 11.Air and power input

Technical parameters

Previous Product:

Eco-friendly Flux sprayer

Next Product:

Full Automatic solder paste Printer YSL-T5

Related Product

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |