Description:

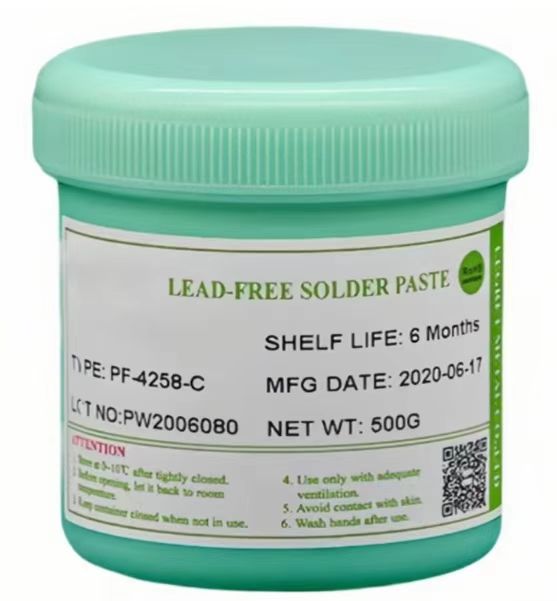

SMT Solder Paste Environmental Friendly High Temperature Lead-Free Solder Paste

Weight:

|

0.5KG

|

Solder Powder Choice:

|

4 tin powder and above

|

Operating Temperature:

|

225-260(℃)

|

Type:

|

No-clean

|

Melting Point:

|

218℃

|

Custom Tiles:

|

Yes

|

Features:

1,The solder joints are bright, full, free of beadsand have moderate viscosity.

2,Less residue after welding and high insulation resistance Will not corrode PCB, and can achieve no washing The requirements of.

3,The continuous printing time is long,there is basically no slump severalhours after printing, the viscosity change is small, and the patch element is not easy to shift.

4,Good wettability,excellent welding performance, and better ICT test performance without misjudgment.

Characteristics:

1.Good printing roll ability and tin attachment, capable of completing the perfect printing for

the pad with the spacing as low as at 0.3mm (T6);

2.The original shape will be maintained for several hours after printing, without basically the

slump, and no deviation will happen to the patch elements;

3.Suitable to various soldering equipment, with the soldering completed without the circumstance filled with

nitrogen, and with the favorable soldering performance within the broader range of the solder- reflow furnace

temperature;

4.With better ICT test performance,without misjudge caused;

5.While in continuous printing, the viscosity of such products has less change, and the steel screen will not

become dry after even 8 hours in terms of the operable life, and will maintain the good printing effect;

6.With splendid soldering performance, and with the proper wet ability at different positions;

7.With less residues after the soldering, with light color solder- Idering and greater isolation impedance,

without the erosionto the PCB, and with the washing-free requirement reached;

8.Can be used for Paster in hole process;

Paste storage

1. Storage temperature and duration: the solder paste should be stored in a sealed environment at 5-10℃, and the validity period.It is usually 6 months, and it needs to be used first in first.

2. Store the solder paste after opening: the solder paste on the screen board must be recycled into a clean and pollution-free empty bottle.After sealing, store separately in the cold storage. Do not mix with the new solder paste, and keep the solder paste after opening.The storage period is 5 days, and those that exceed the storage period should be scrapped to ensure product quality.

3. When the previous batch of unused solder paste is used again, if it is found to be dry, a small amount can be added.Solder paste special thinner stir well before use.