|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

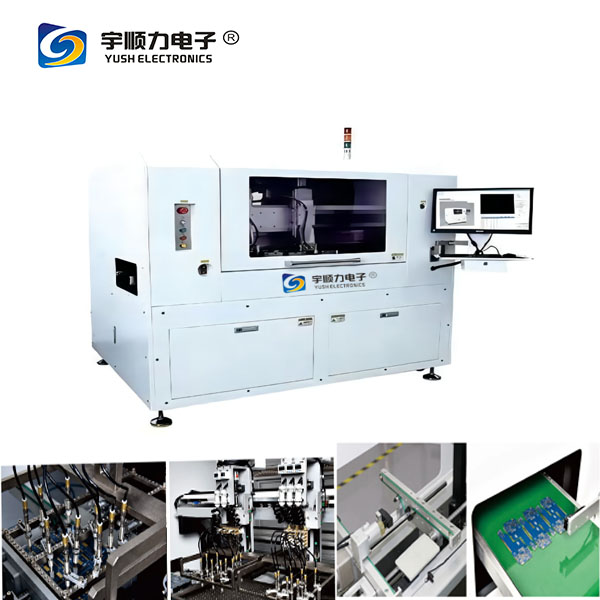

| PCB Routing / separator |

Description:

On-line Lower Plate Machine YS-700 Fully Automatic Loading Plate Machine

YS-700 is mainly used for docking splitter and plug-in machine or DIP production line indispensable automation equipment, connecting splitter cut PCBA board, downward wave soldering reflux vehicle, equipped with XYZR axis and 180 degree reversal mechanism, will be cut PCBA into the loader in order to realize production line automation, save manpower and reduce personnel contact with electronic products, improve product quality.

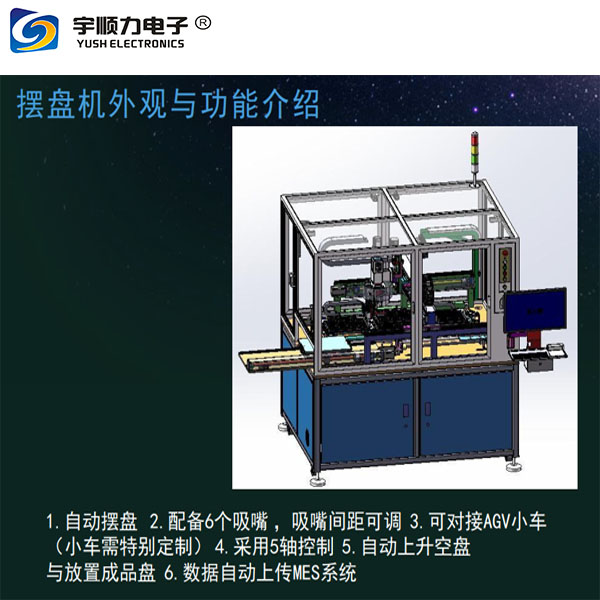

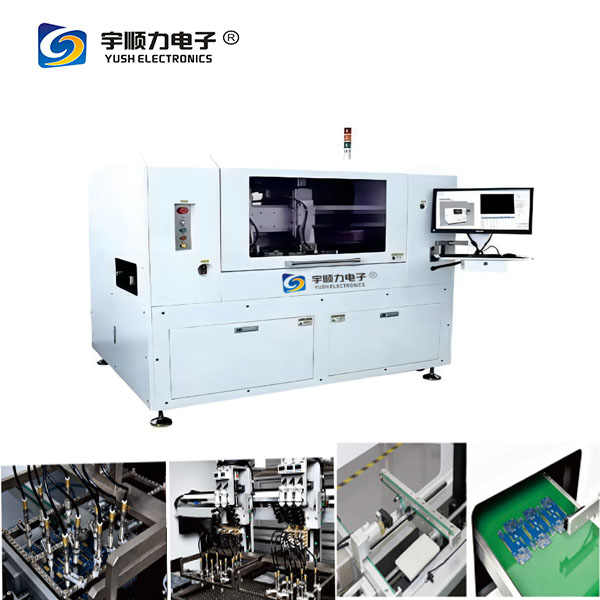

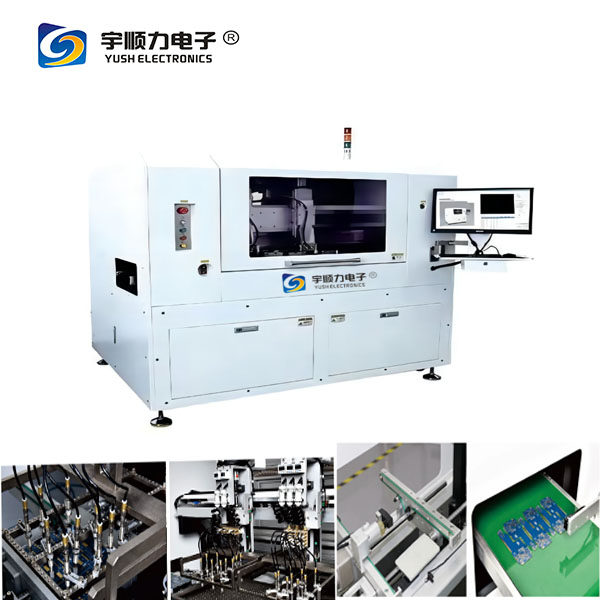

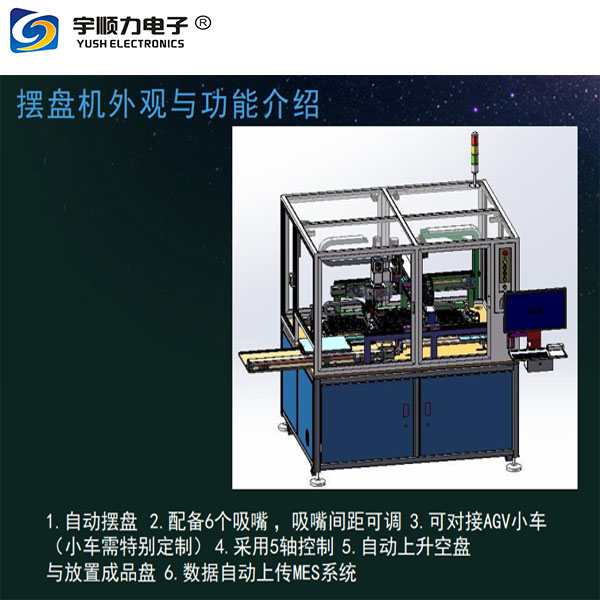

Details Automatic Tray Plate Closing Machine YS-800

YS-800 is mainly used for connecting PCBA board cut by splitting machine. It is equipped with XYZ axis to put the splitted PCBA into empty Tray disk in order by manipulator. It realizes automatic loading, saves manpower, reduces personnel's contact with electronic products and improves product quality.

Plate feeder (board feeder) CGLD-880A

Performance characteristics: 1) Mainly used as the source of SMT production line, PCB boards are stored and transported to back-end equipment through material frame, which has the function of automatic feeding boards. 2) The control system is controlled by PLC, and the touch screen is used in the operation interface. The performance is stable and the operation is convenient. 3) The frame structure is welded by sheet metal, constructed by aluminium profiles, and the surface is sprayed with paint. 4) The lifting structure adopts motor lifting setting, and the effective setting step can be chosen; 10mm, 20mm, 30mm, 40mm, and frequency converter can be selected. 5) Pneumatic cylinder is used for feeding plate, and automatic ventilation device can be installed to ensure that PCB will not be pushed down and reduce process loss. 6) Bottom-in and bottom-out are adopted to effectively shorten the time of frame-changing. 7) Equipped with standard SMEMA signal port, it can be connected with any other equipment online. 8) Anti-static cover and L-type plate feeder can be installed as required.

Technical parameters: 1) PLC control system: Panasonic 2) Touch screen: Panasonic 3) Lift motor: Panasonic 4) Cylinder: CMC/ADK 5) Sensors (SENSOR): Panasonic, Omron 6) Relay: Omron 7) Power Switch: Omron 8) PCB transmission direction: left-right or right-left 9) PCB conveying height: 900 + 20mm 10) PCB conveying thickness: 0.5-4.0T 11) PCB Conveyor Large Size: M-TYPE 330*250mm L-TYPE 460*330mm LL-TYPE 510*380mm XL-TYPE 510*460mm 12) Magazine time: 15-25t 13) Delivery time: 6-15 seconds per piece 14) Placeable material frame: top two, bottom two or top one 15) Power supply: AC110V/220V 50-60Hz 0.5A 110W 16) Gas supply: 4-6 Kgf/cm 2 17) Weight: M-TYPE 185KG L-TYPE 205KG LL-TYPE 235KG XL-TYPE 265KG 18) Shape size: M-TYPE 1415mmL*880mmW*1710-2055mmH L-TYPE 1725 mmL*960 mmW*1710-2055 mmH LL-TYPE 1900mmL*1020mmW*1710-2055mmH XL-TYPE 1900mmL*1200mmW*1710-2055mmH

Previous Product:

Hot Bar Soldering Machine Thermode Hot Bar Welding Machine For SMT Line

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |