|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

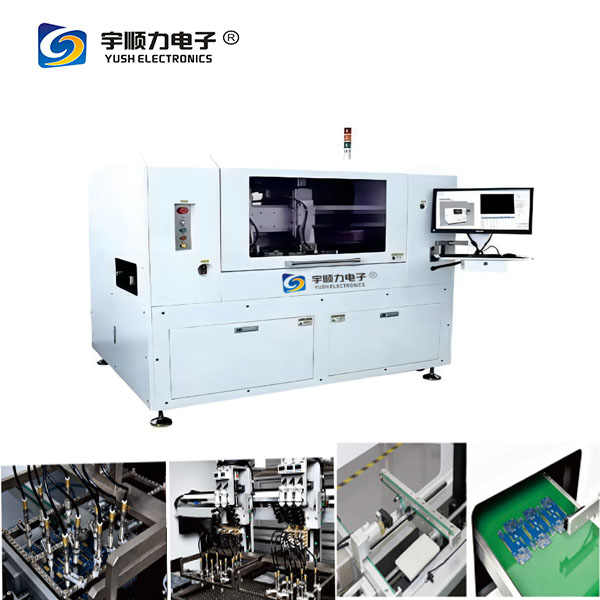

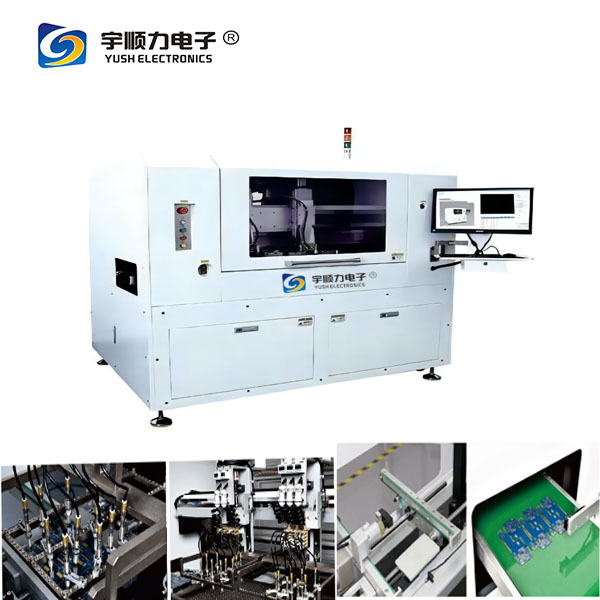

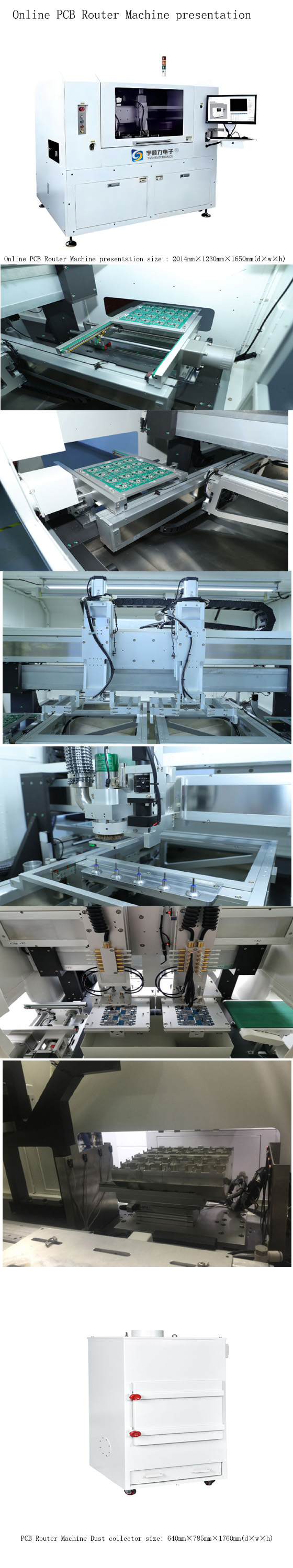

| PCB Routing / separator |

Description:

Machine Introduction

1.In-line automatic PCB Separator can load,cut,and un-load PCBs automatically to meet the needs of automatic factory.

2.Can automatically adjust width to adapt to the size of PCB.Can automatically differentiate finished PCB board from waste-

material after cutting for saving labor cost.

3.Equipped with high-speed CCD vision alignment system in all series of products to enhance the precision in cutting and

efficiency in operation.

4.Adopt the computer vision with high-quality CCD to automatically position the mark points and enhance the accuracy of

cutting.

5.Provide duel worktables for placing and cutting PCB in parallel to enhance the efficiency of operation.

6.Use high-speed spindle with small cutting stress to precisely cut PCB of any shape. 7.The system has auto-focusing function and requires no manual operation to adjust focus.

8.The EMS central control system can be linked to upper information management stystem and provide integrated production

data to monitor the status of equipment at any time.

Previous Product:

In- Line Vision- Aided Automatic PCB Separator YS330AT

Next Product:

On-line depaneling Machine YSL360AT

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |