|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

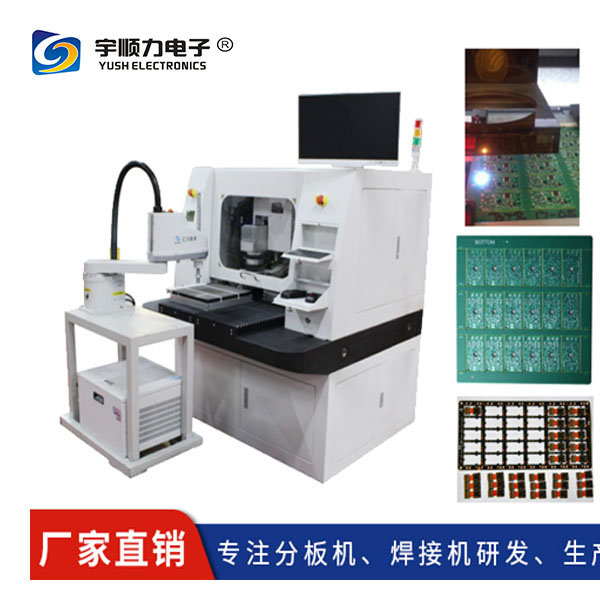

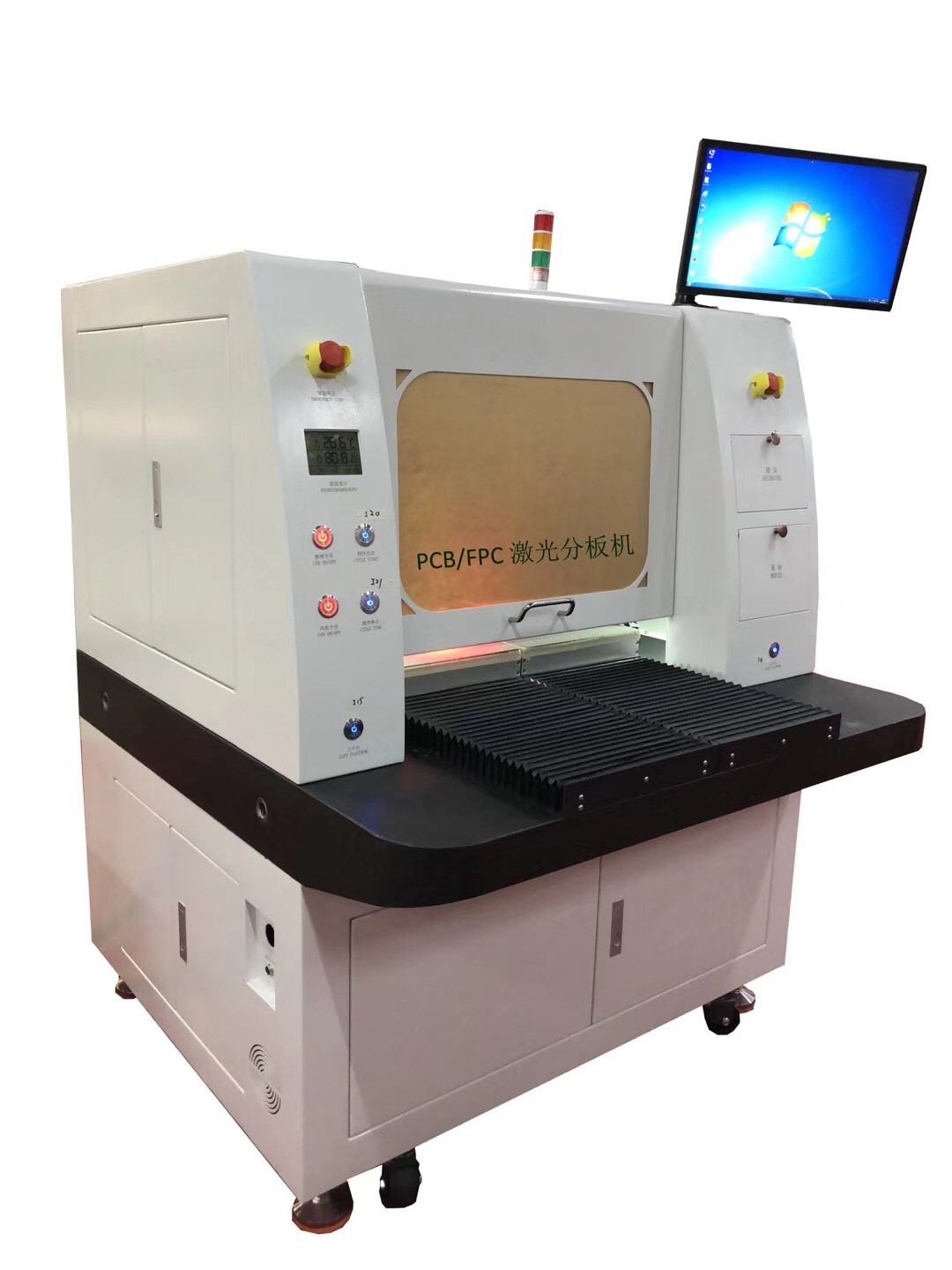

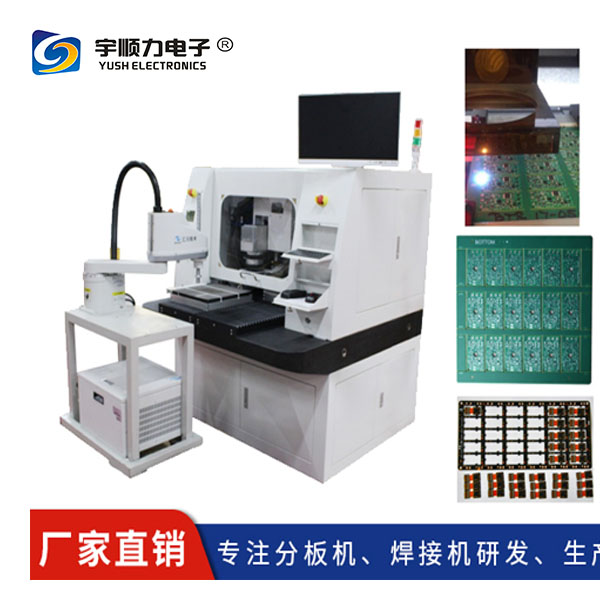

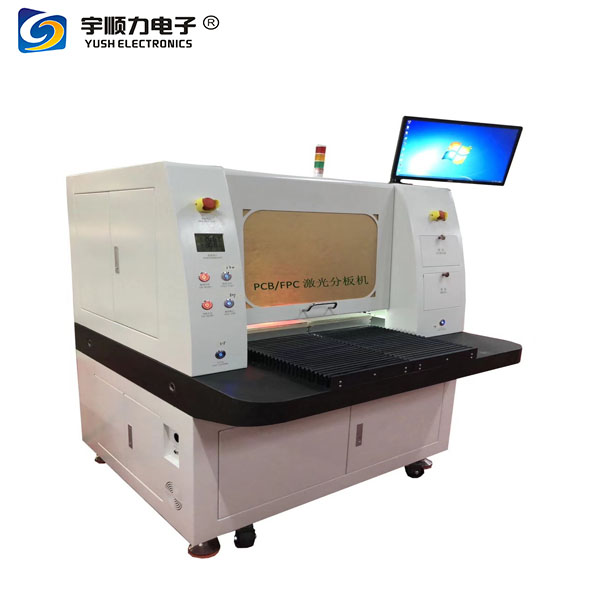

| PCB Routing / separator |

Description:

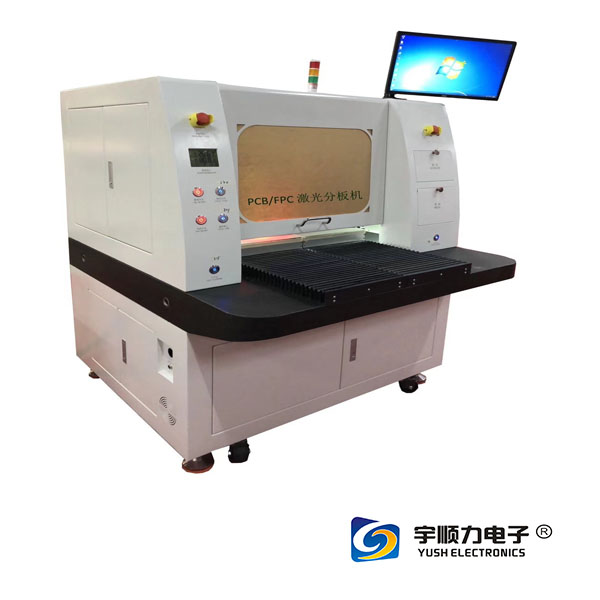

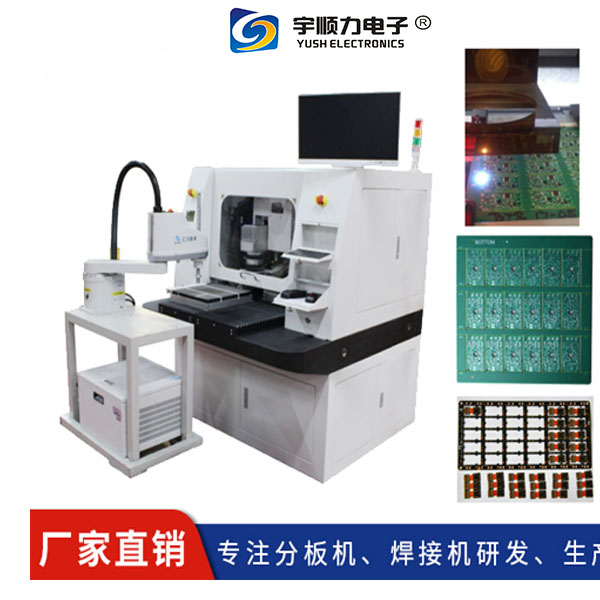

Gong-board machine-YSATM-4C

Basic specification (1) Cutting speed of X and Y: 0-100mm/s (2) Machine repetition accuracy: +0.01mm (3) Pressure supply: 4.5kg/cm2 or more (4) Power consumption: 3KVA (5) X, Y1, Y2, Z control methods: industrial IPC and PC (6) X, Y1, Y2, Z drive mode: AC optical fiber servo motor (7) Machine operation and data storage: PC system (8) Dust collection: upper dust collection 2HP (9) Dust collector voltage: 380V3 (10) Size of upper dust collector: L650 * W400 * H1350mm (11) cutting accuracy: ± 0.05mm (12) Spindle speed: maximum 100000 PM (13) Main voltage: 220V150/60HZ

Benefits:

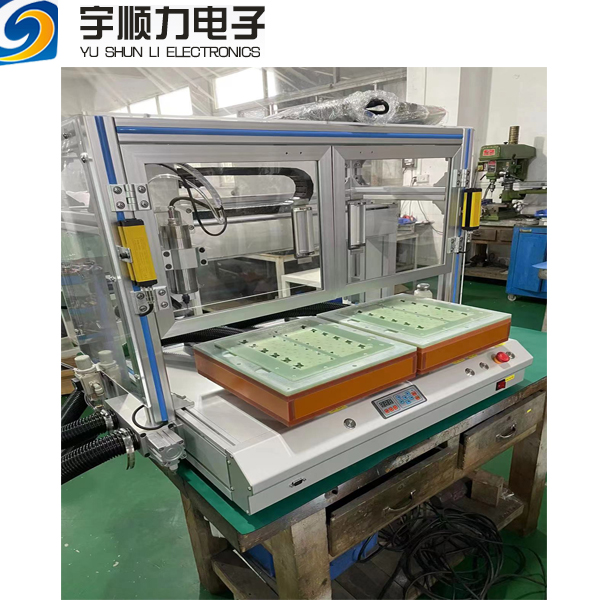

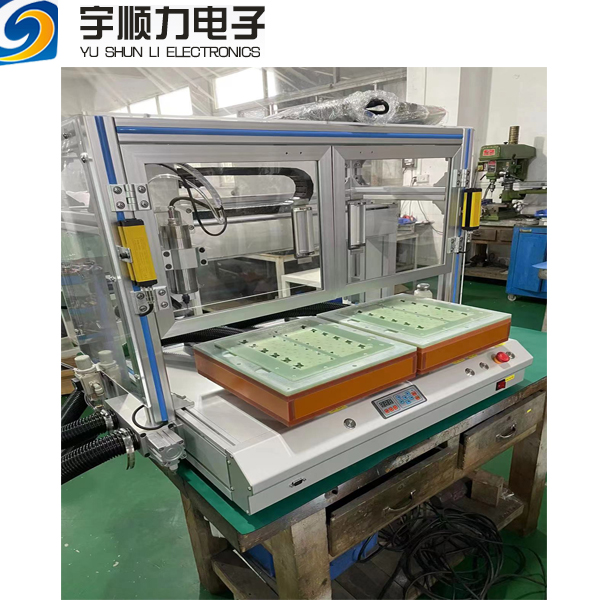

1) Double sliding device is adopted to reduce cutting waiting time and improve production capacity. 2) Avoid artificial flaps caused by tin cracks and component damage. 3) Avoid blunt or folding caused by mechanical stress. 4) Suitable for arc and wire cutting of finished plate. 5) Applicable to the final cutting of mobile phones, PDA, PC interface cards and other small parts of the bottom board.

Workpiece Size Machine Size W.D.H Net Weight Double table YSATM-4C-IN-AS standard 300*300 mm 1680*1298*1700 mm 1100 KG Double table ysatm-4c-in-aw widened 500 * 450mm 1902 * 1373 * 1700mm 1400KG

Product characteristics: On-line automatic PCB separator can automatically load, cut and unload to meet the needs of automatic factory. * It can automatically adjust the width and receive the PC board. At the same time, the finished PCB board and scrap can be identified automatically after cutting, thus saving labor costs. With high-speed CCD and automatic vision alignment system, cutting accuracy and operation efficiency are greatly improved. Use high-speed spindle to cut PCB, reduce cutting stress and improve accuracy. It is suitable for any type of PCB. Double table movement can cut and place PCB at the same time to improve operation efficiency.

Operational vision: Diagrammatic window operation page, easy to learn and operate. Edit the cutting program directly on the screen.

Previous Product:

Electronics Industry Screw Tightening Machine With Screw M2.0 - M5.0

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |