|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

| PCB Routing / separator |

Description:

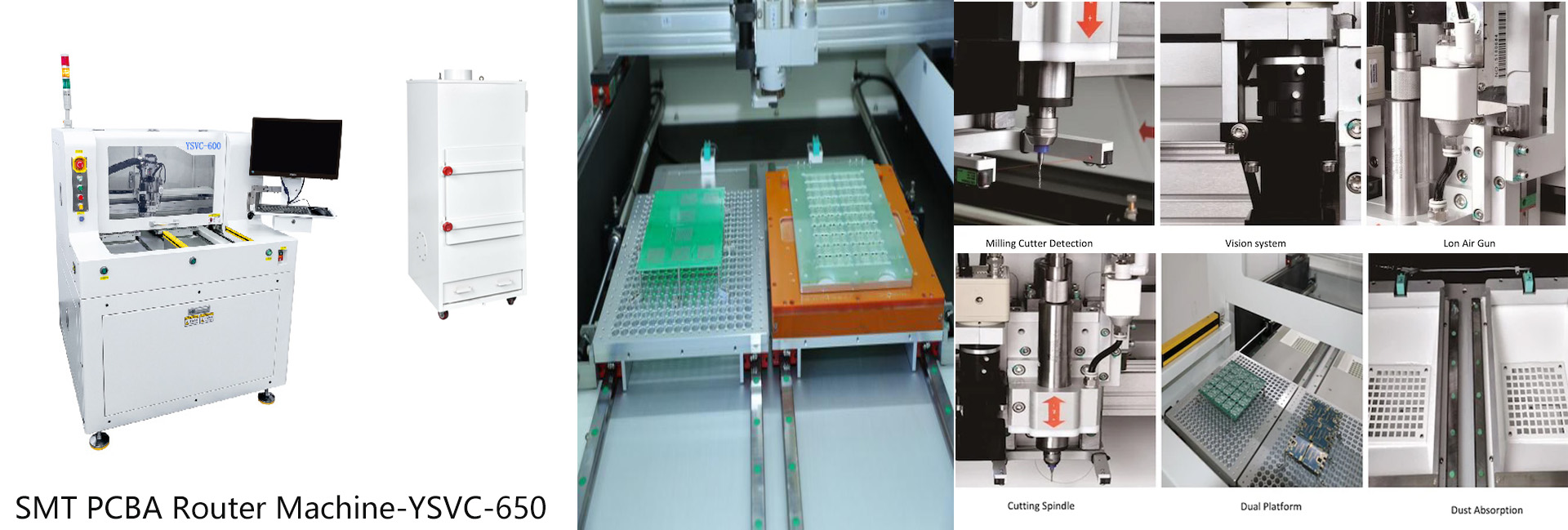

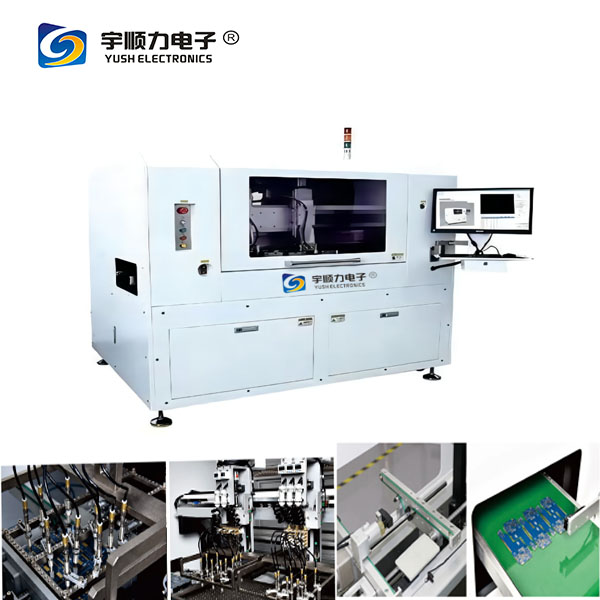

YSVC-650-PCB Cutting Milling Cutter Automatic Plate Breaker

Product Profile: 1. The PCB cutting and milling cutter automatic splitter replaces manual breaking, V-CUT or PUSH cutting defects, effectively improves product quality and reduces external stress on the product. 2. Configuration of high-pixel CCD lens, assistant program teaching and editing functions, higher accuracy and more accurate. 3. Cutting PCB board with double platforms can reduce waiting time and improve productivity effectively. Fourth, the functions of right and left workbench replication, block replication, display, multi-angle connection board replication, one-step tracking and modification, block editing and modification, accurately simplify the time of program production and improve editing efficiency. 5. Automatic MARK point positioning and correction system, real-time display of moving path and Simulation of route tracking, effectively improve the cutting accuracy. 6. Vacuum cleaner and high voltage electrostatic eliminating device made by high-power imported fan can improve the effect of dust collection. 7. Tool life monitoring of PCB cutting and milling cutter automatic splitting machine to prolong the life of milling cutter.

Product characteristics: A. The whole series is equipped with high-speed CCD vision automatic correction system to improve cutting accuracy and operation efficiency. B. High-speed spindle splitting board, small cutting stress, high accuracy, suitable for irregular shape PCB board. C. Dual working platform, can simultaneously perform cutting and circuit board placement, improve operational efficiency. D. Self-developed dust collection device, low noise, improve efficiency, easy maintenance and cleaning.

Specification parameters: 1. High Definition Color CCD Camera 2. Power consumption: 3KW 3. Weight: 1000KG 4. Spindle: MAX60000RPM 5. Cutting accuracy: +0.02 mm 6. Repetition accuracy: +0.01 mm 7. Operating Interface: PC WINDOW Platform 8. Dust collector: 3HP 9. Voltage of main engine and dust collector: 220V1/380V3 10. Cutting speed: 0-100mm/s 11. CCD recognizes MARK points with visual compensation function 12.X.Y Travel: 290*350 mm 13.X.Y.Z Driving Mode: AC Servo Motor

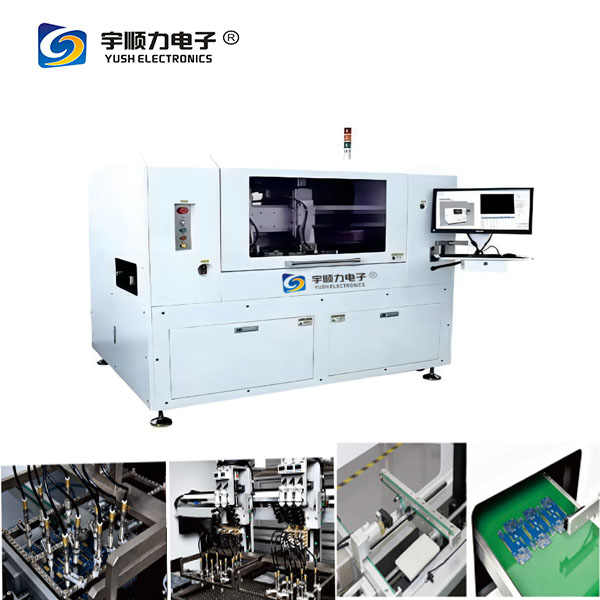

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |