|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

| Laser Cutting Machine |

Description:

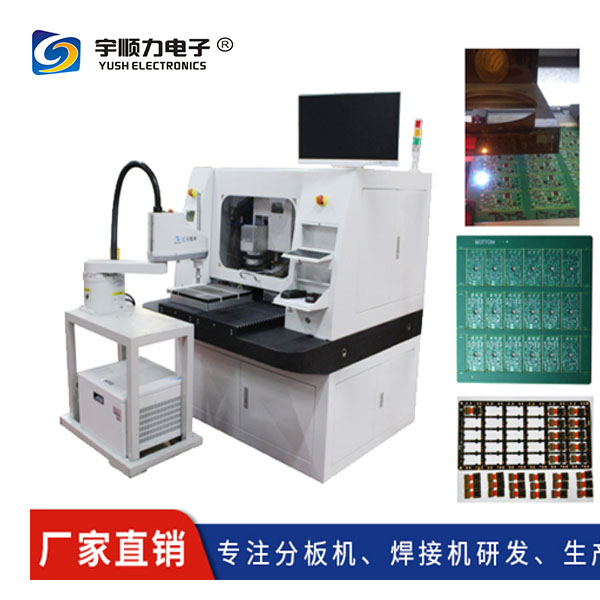

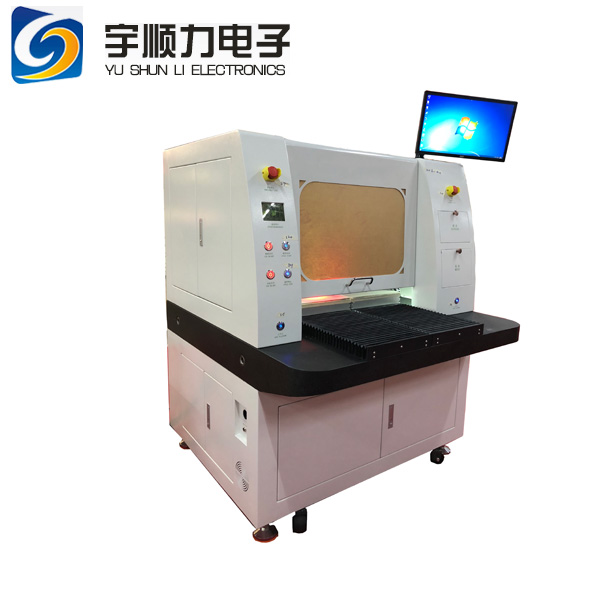

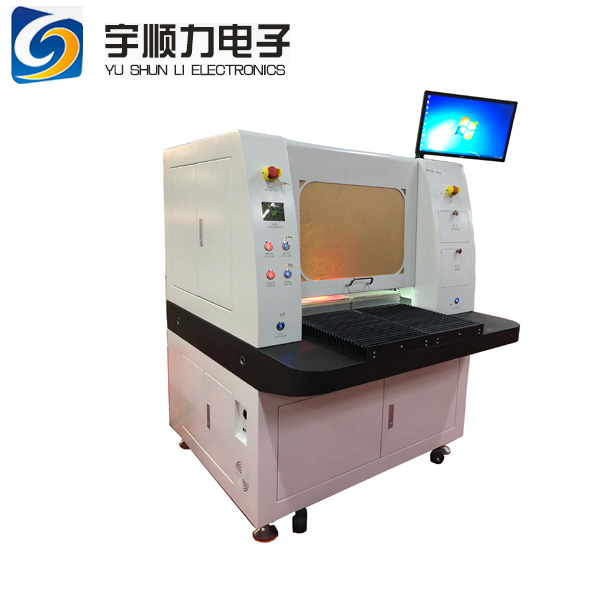

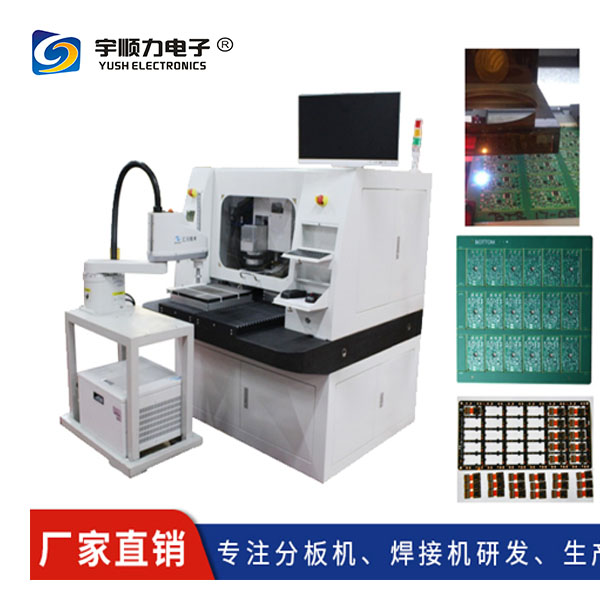

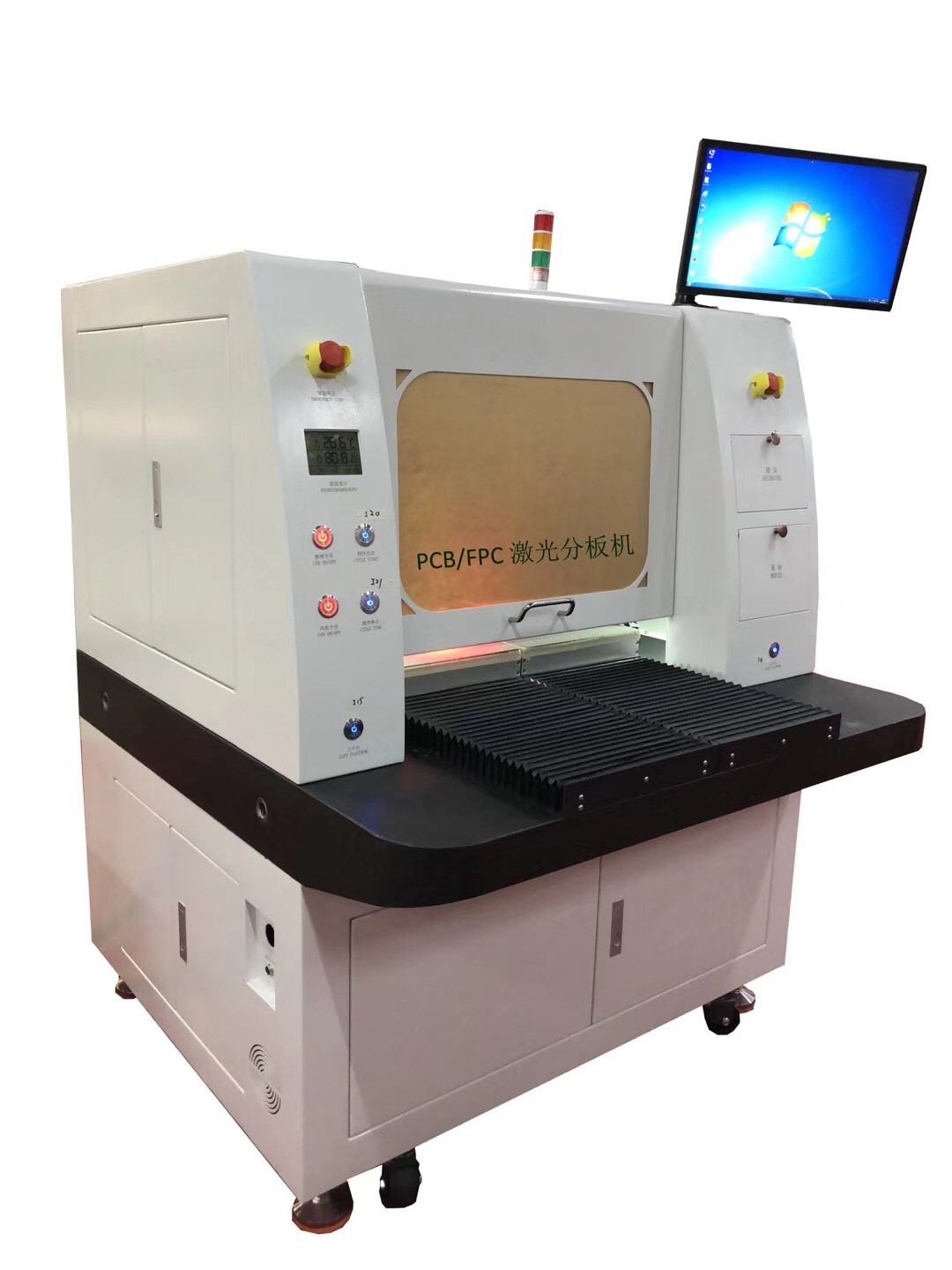

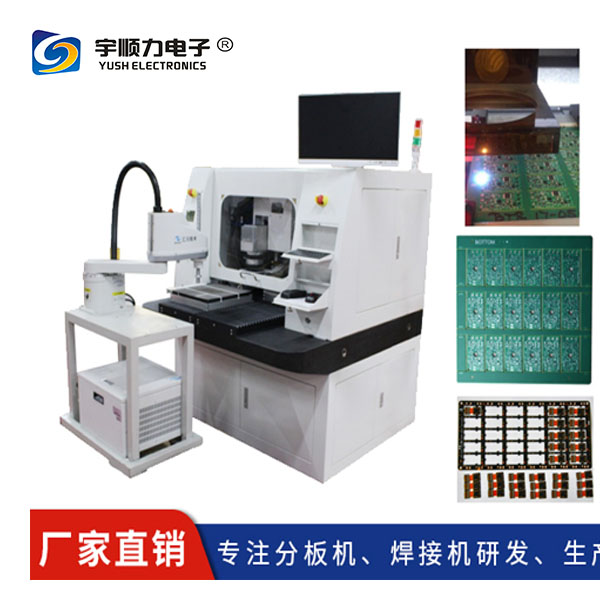

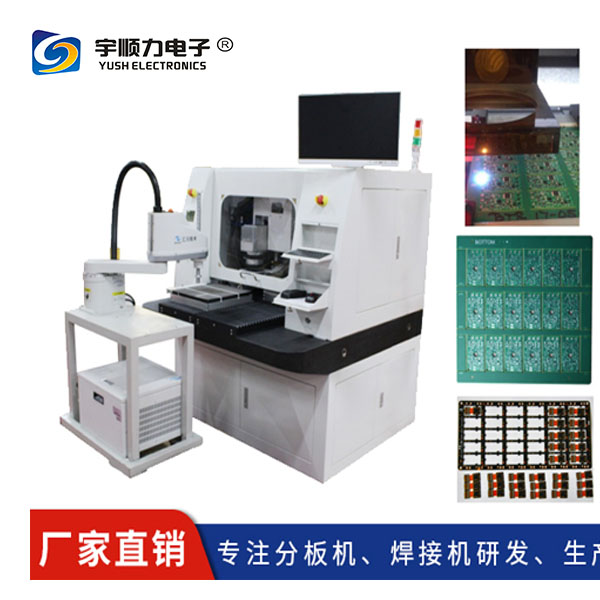

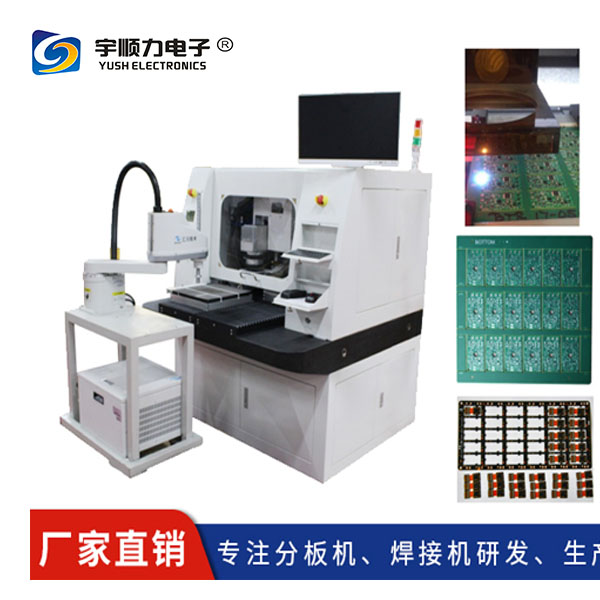

Laser Cutting Machine-YSV-7A/6A (Double Platform)

Technical parameters of the project: (1) Laser machine weight 2000KG (2) Main body size (length * width * height) 1680 mm * 1650 mm * 1800 mm (3) Laser power 10W/15W (ultraviolet) (4) Scanning speed 1-900 mm/ms (5) Cutting width 350 mm * 400 mm / 350 mm * 400 mm (double platform) (6) Laser power supply AC220V/3.5KW (7) Accuracy of the whole machine (+20 micron) (8) The width of the slit is 20+5 um (9) Platform positioning accuracy (+2 micron) (10) Platform repetition accuracy (+2 um) material thickness (<1.5 mm) depending on the actual material. (11) Laser Source Ultraviolet Laser

Characteristic: 1. Laser cutting machine YSV-4A, double platform, greatly improve production efficiency, is specially designed for FPC and PCB processing equipment. 2. High-performance lasers: Solid-state ultraviolet lasers with international first-line brands have the advantages of good beam quality, small focus spot, uniform power distribution, small thermal effect, small slit width and high cutting quality, which are the guarantee of perfect cutting quality. 2. Efficient and fast FPC/PCB shape cutting, drilling and covering window opening, fingerprint identification chip cutting, TF memory card partition board, mobile camera module cutting and other applications. 3. Full automatic positioning: High-precision CCD automatic positioning, focusing, so that positioning fast, accurate and high accuracy, without manual intervention. 4. Simple operation, realizing the same type of one-key mode, greatly improving production efficiency. 5. Cut into blocks, layers, designated blocks or selected areas and shape directly. Cut edges are smooth, smooth, without burrs and glue spills. 6. The product can be arranged in matrix for automatic positioning and cutting, especially for fine, difficult, complex patterns and other shape cutting. 7. Exhaust gas treatment system: The suction system can eliminate all cutting exhaust gas, avoiding the harm to operators and pollution to the environment.

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |