|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

| Hot Bar Soldering Machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description:

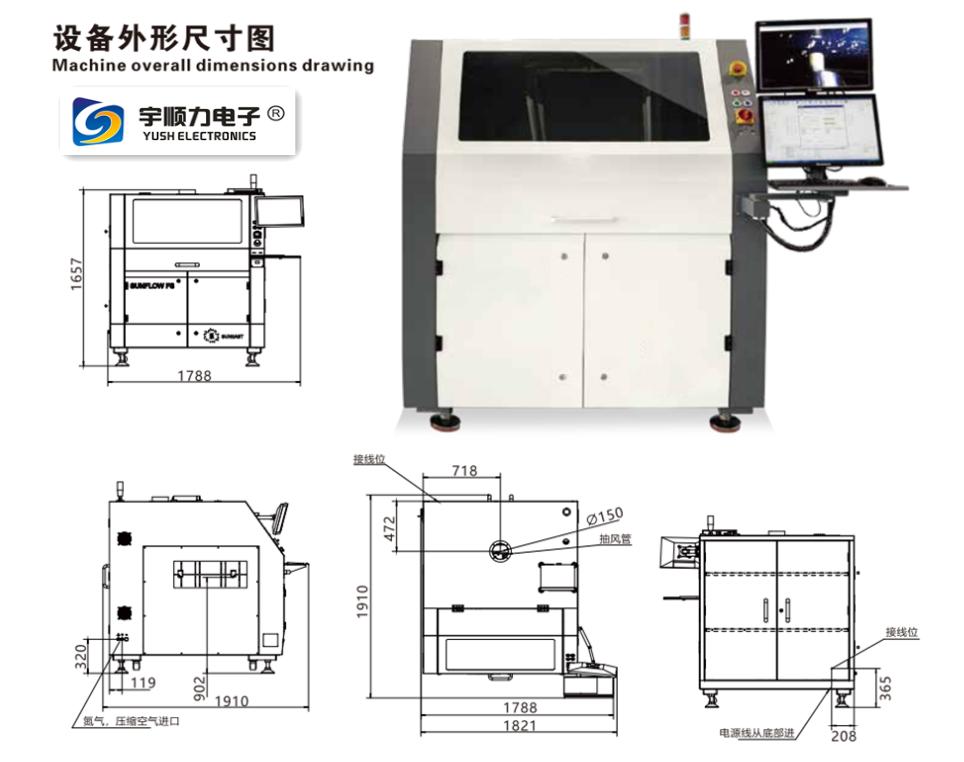

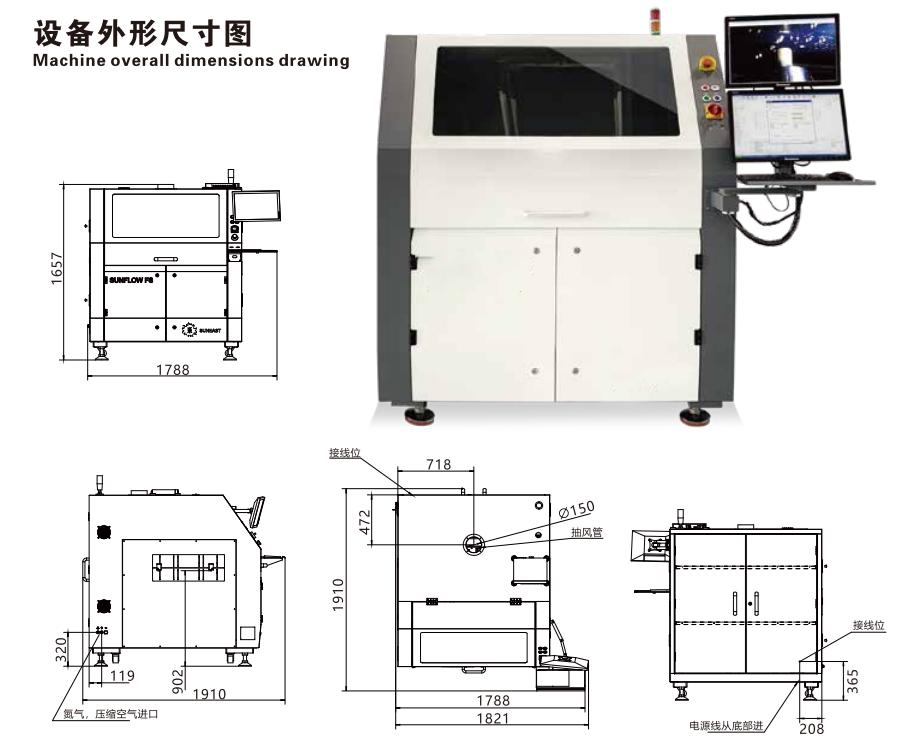

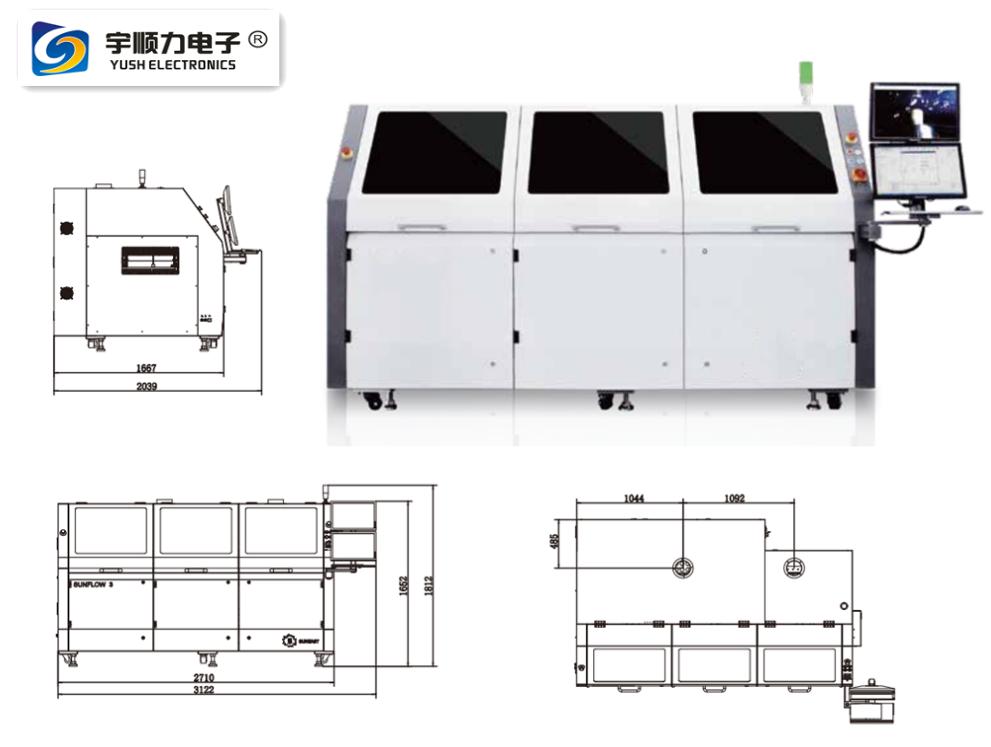

UX series oven is based on customer demand and adopts modular, digital and humanized design. With superiority in function, performance, stability, reliability, security, maintainability,operability and humanization,it doesn't only reduce the operating cost, but also provides qualified products for quality,quantity and production with strong guarantee.It can be described as the "peak" work in the fifield of Wave soldering products, and the preferred "brand products" for customer investment.

Integrated spray fluxer unit(selective spray device is optional)

Drawer type and modular structure preheating zones

Cast iron soldering pot with special anti-corrosion coating

Manual width adjustment with digital display

Solder pot electric/manual lifting in and out

1.The transportation system adopts section floating structure, effectively prevent guide rail deformation, new titanium alloy double hook finger,non-stick tin, direct linkage buffering, aluminum guide rail, more smooth.

2.Spray unit integrated module design, through the fast connector connected with the machine; adopts new precision nozzle, which can achieve

high efficiency, uniform atomization coating effect and meet the process requirements of water flux.

3.The preheating system adopts micro-hot air + infrared heating tube, three-section preheating temperature zone, drawer type modular design,flexible selection of mixed preheating mode, uniform and stable temperature.

4.Forced air cooling system (Water chiller is optional).

5.The solder pot system adopts special material for pot, and anti-corrosion treatment for inner surface. (New nozzle fixed mode, easy to remove and assembly; the solder pot temperature control precision is ±2℃; solder pot electric/manual lifting in and out, easy to operate.

6.Windows 7 operating system, Chinese/English intelligent software, with parameter setting, saving, reuse, remote monitoring functions. Process

profile/data automatic storage function, temperature profile test function.

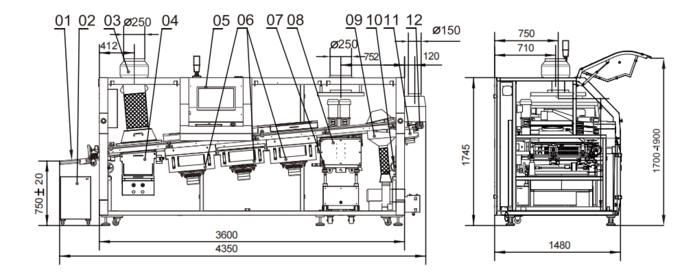

01 Buffer system

02 Flux supply system

03 Exhaust fan

04 Flus spray system

05 LCD

06 Pre-heater

07 Solder pot lifting unit

08 Dual wave solder pot

09 Cooling system

10 Angle adjustment controller

11 Finger cleaning system

12 Conveyor system

Previous Product:

Vertical Reflow Oven S SERIES

Related Product

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |