|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

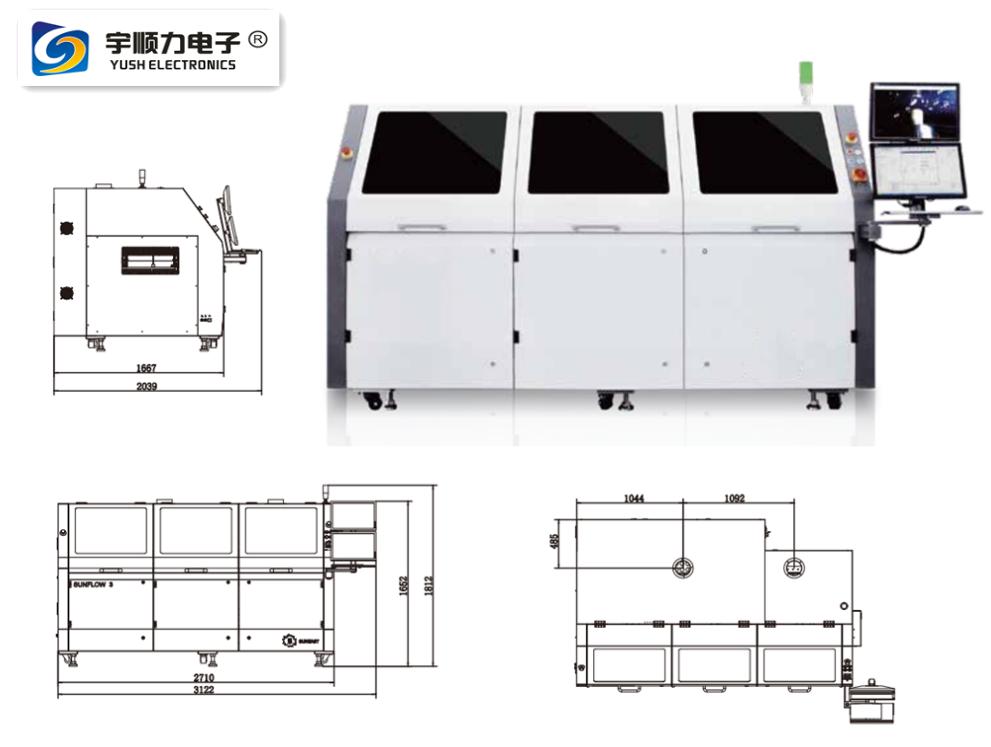

| Hot Bar Soldering Machine | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Description:

Features:

Standard machine basic structure module

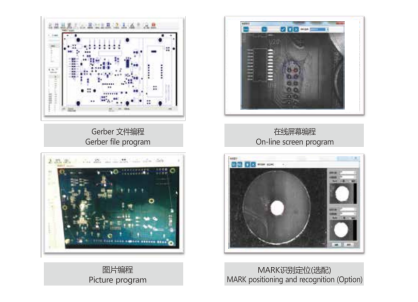

Fast and convenient programming system

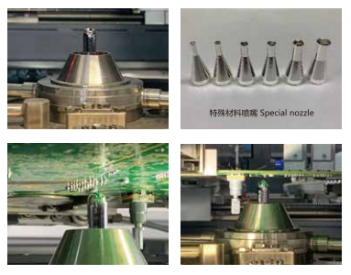

Stable and high-quality welding----welding module

Using an electromagnetic pump, compared with a mechanical pump, the electromagnetic pump has stable wave peaks during operation, no mechanical wear of the movement, and produces very little waste. In addition, the welding module adopts a high-precision motion system to ensure the accuracy of the welding process. , The colleague cooperates with the special process, which can greatly eliminate the phenomenon of tin connection. In terms of user experience, it provides welding monitoring cameras and automatic detection of wave height, which greatly improves the user experience.

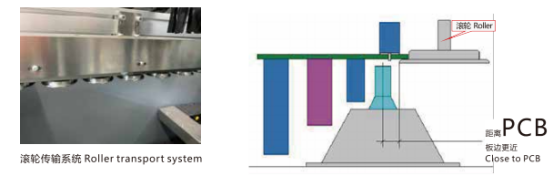

Transmission system---transmission track

The transmission system adopts roller conveying, which increases the welding space and is more conducive to the welding of components close to the edge of the board.

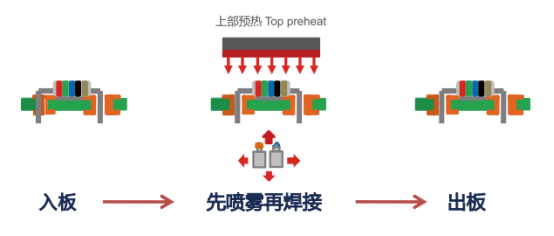

selective soldering process

High precision spray---spray module

Using an electromagnetic pump, compared with a mechanical pump, the electromagnetic pump has stable wave peaks during operation, no mechanical wear of the movement, and produces very little waste. In addition, the welding module adopts a high-precision motion system to ensure the accuracy of the welding process. , The colleague cooperates with the special process, which can greatly eliminate the phenomenon of tin connection. In terms of user experience, it provides welding monitoring cameras and automatic detection of wave height, which greatly improves the user experience. Previous Product:

Online independent welding machine

Next Product:

PCBA Single-sided cleaning machine

Related Product

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |