|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

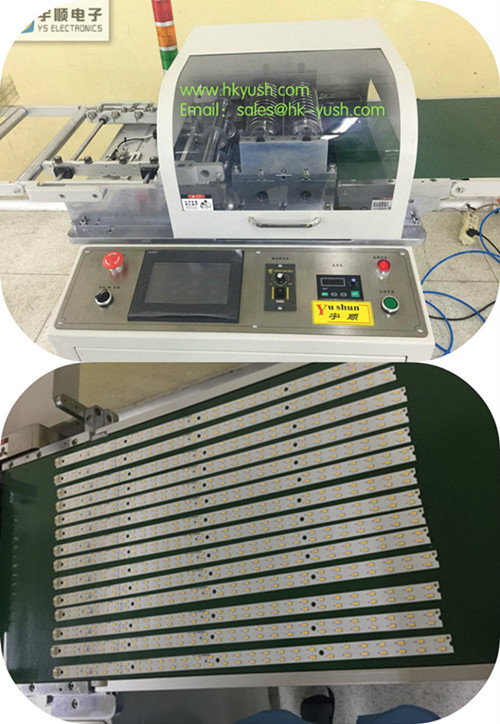

| PCB Separator |

Description:

Details:

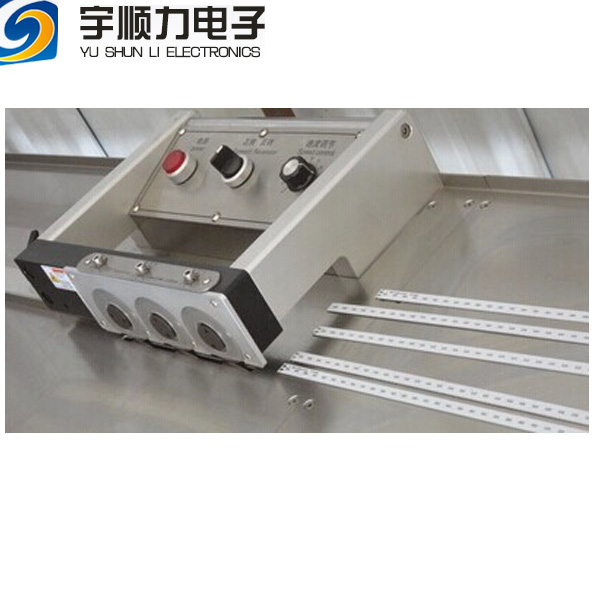

YSVJ-650 is equipped with 2 groups of blades can make twice cutting process for one PCB, the distance between upper and lower cutter can be adjusted adjusted, even easily separate 3.5mm aluminum board without any burrs and deformation, all cutters are made of SKD11 High speed steel with long service life

The pitch of cutter can be changed by replacing spacers to meet different width of panel board requirement.

YSVJ-650 is equipped with automatic PCB clamping and loading system which can be easily connected with automatic product ion line, SM Ema connector is optional.

Full English operation interface, easy to operate.

The machine adopted touchscreen and PLC control system which can monitor production information, easy to operate.

Features:

1. YSVJ-650 is equipped with 2 groups of blades which can cut aluminum and FR4 LED board without burrs and deformation, it greatly improve the production efficiency and reduce labour costs. 2. YSVJ-650 create a unique design of 2 sets of blades .it can make twice cutting process for one PCB, the distance between upper and lower cutter can be adjusted adjusted, even easily separate 3.5mm aluminum board without any burrs and deformation. 3. YSVJ-650 is equipped with automatic PCB clamping and loading system which can be easily connected with automatic production line. 4. Cutting speed is adjustable. 5. All blades are made of endurable SKD11 high speed steel with long service life. 6. The machine adopt touch screen and PLC control system which can monitor production information, easy to operate. 7. Machine is equipped with safety protection device. 8. Suitable cutting material of PCB: aluminum, FR4, glass fiber.

Standard configuration:

1. Multiple Groups Of Blades PCB Separator YSVJ-650. 2. Automatic PCB clamping and loading device. 3. 1 year parts warranty. 4. 1000mm output belt conveyor. 5. 2 groups of cutter module. 6. 20 pcs of circular blades. 7. 40 pcs of customized spacers 8. 1 year parts warranty. Optional configuration: 1. Circular blade 901. 2. Customized spacer. 3. 1500mm Outlet belt conveyor instead of standard 1000mm outlet belt conveyor. 4. Optional 1000mm inlet conveyor. 5. Optional 1500mm inlet conveyor. 6. SMEMA connector. 7. Modified to cut maximum280mm-330mm width PCB Previous Product:

Macchina manuale del PWB Depanelizer del separatore del PWB con il coltello rotondo-YSVJ-650

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |