|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

| PCB Separator |

Description:

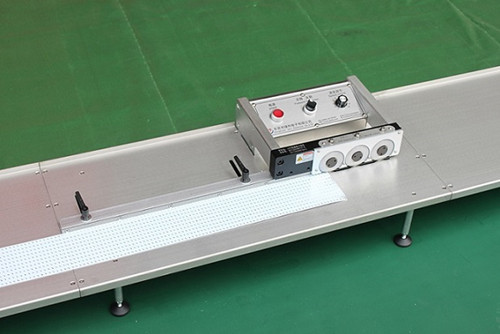

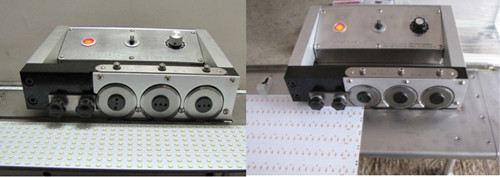

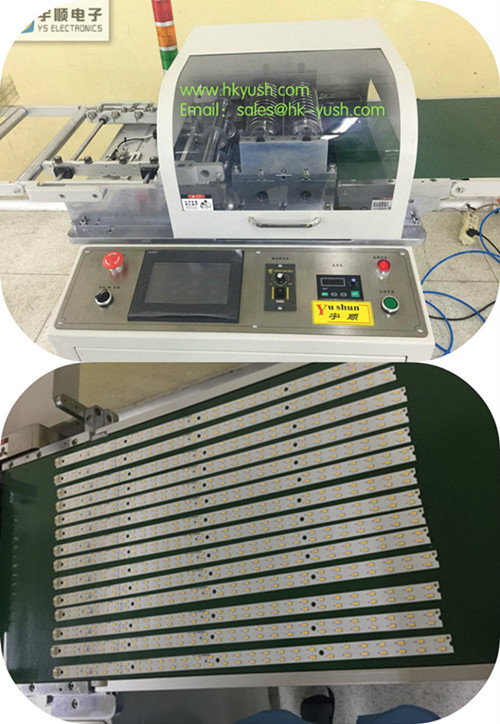

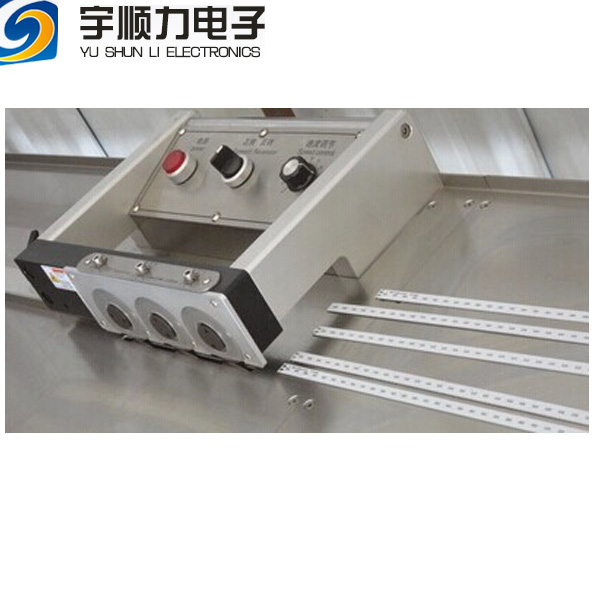

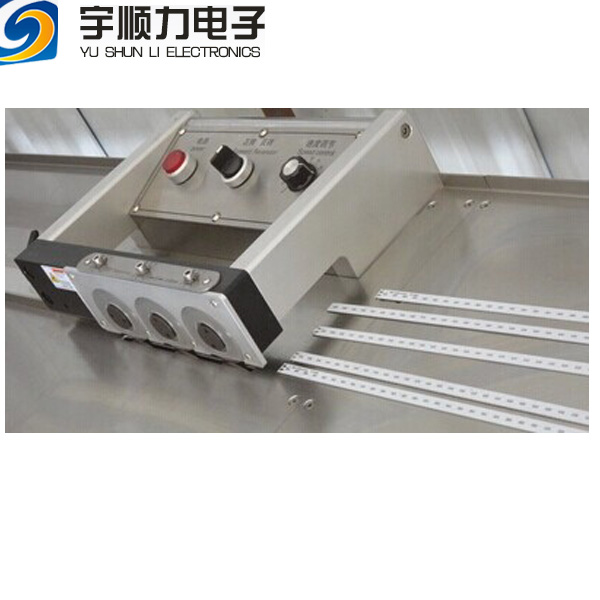

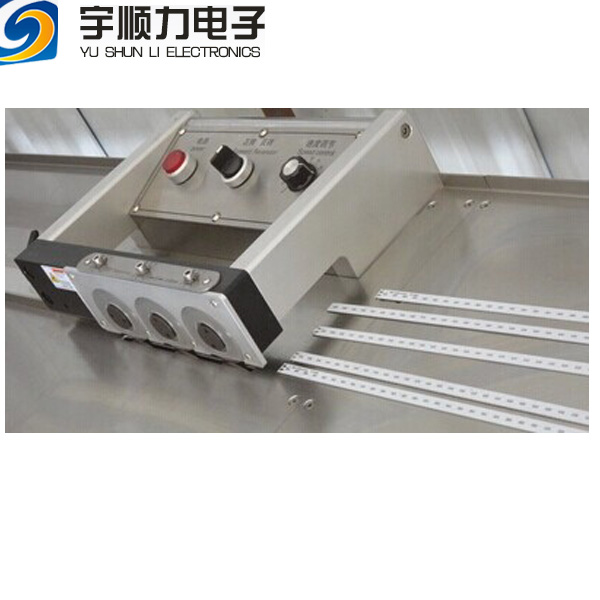

Italy Pneumatic FPC / PCB cutting machine,PCB depaneling for metal PCB-YUSH Electronic Technology Co.,Ltd Model: YSVC-3S Cutting Lenght : Max 1.5 M Led Light board . Voltage : 110V / 220V Certificates : CE Mark Weight : 98 Kg . Platform length: 1.5 M / 2.4 M Cutting Board : v-cut pcb board , FR4 board . LED Aluminum board .

Feature; Guide can be adjusted vertically to suit different PCB thickness; Clearance between the circular blades can be precisely adjusted with the knob; Upper and lower circular blades can be re-used after regrinding; Shape and sizes of the circular blades can be made according to customer's specifications; Machine Size: 420mm X 280mm X 400mm; Minimize Speed: 0-400mm/s Minimize thickness: 1.0-3.5mm

Previous Product:

laser key cutting machines

Next Product:

pcb tooling

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |