|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

| PCB Cleaning Machine | ||||||||||||||||||||||||||||||||||||||||

Description:

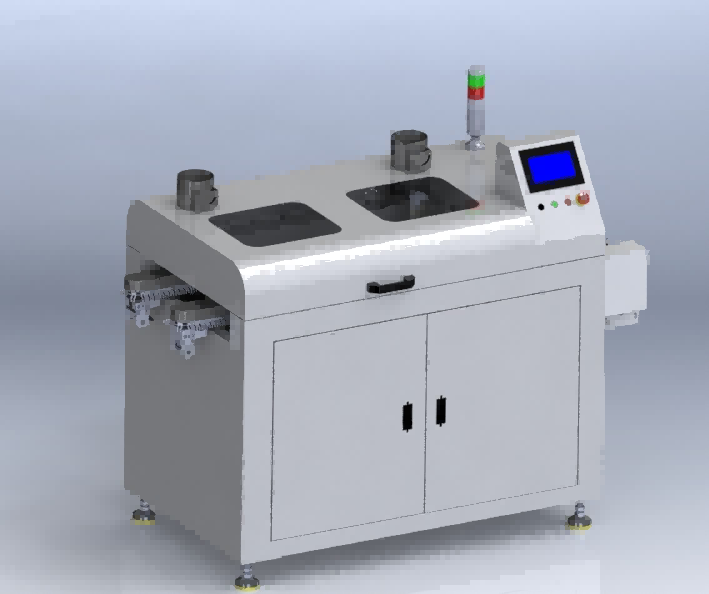

CE Ultrasonic Pcb Cleaning Machine / 32 L Ultrasonic Cleaning Device

Product Feature:

1. Standard leaning chemicals can be add into machine manually or using dosing pump to add pure chemicals and DI water automatically according to different ratio(5%~20%).

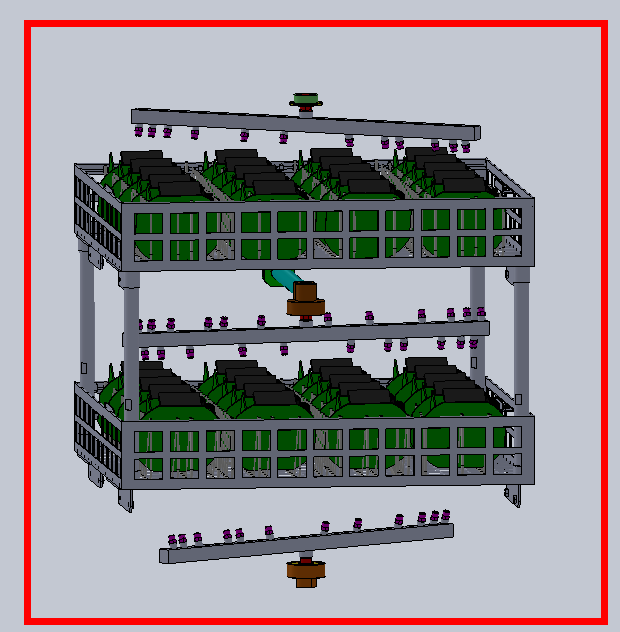

9. Built-in resin pipe out filtration system to effective filtrate all kings of impurity substance like COD,BOD,PH…etc. 7. Total SUS304 stainless structure, Strong Acid and alkaline resistance, more than 10 years life span. 8. layers cleaning baskets: big 2 layers 645mm(L) ×560mm(W) × 200mm(H) x 2

9. Easy Chinese operation interface, quick and easy cleaning process parameters setting, procedures can be stored and called out; different password can be set Machine SpecS:

Previous Product:

AC220v Automatic Pcb Cleaning Machine 12 Nozzles In One Time

Related Product

|

||||||||||||||||||||||||||||||||||||||||

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |