|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

| Wave Soldering Machine | ||||||||||||||||||||||||||||||||

Description:

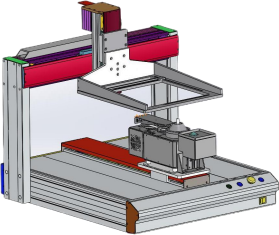

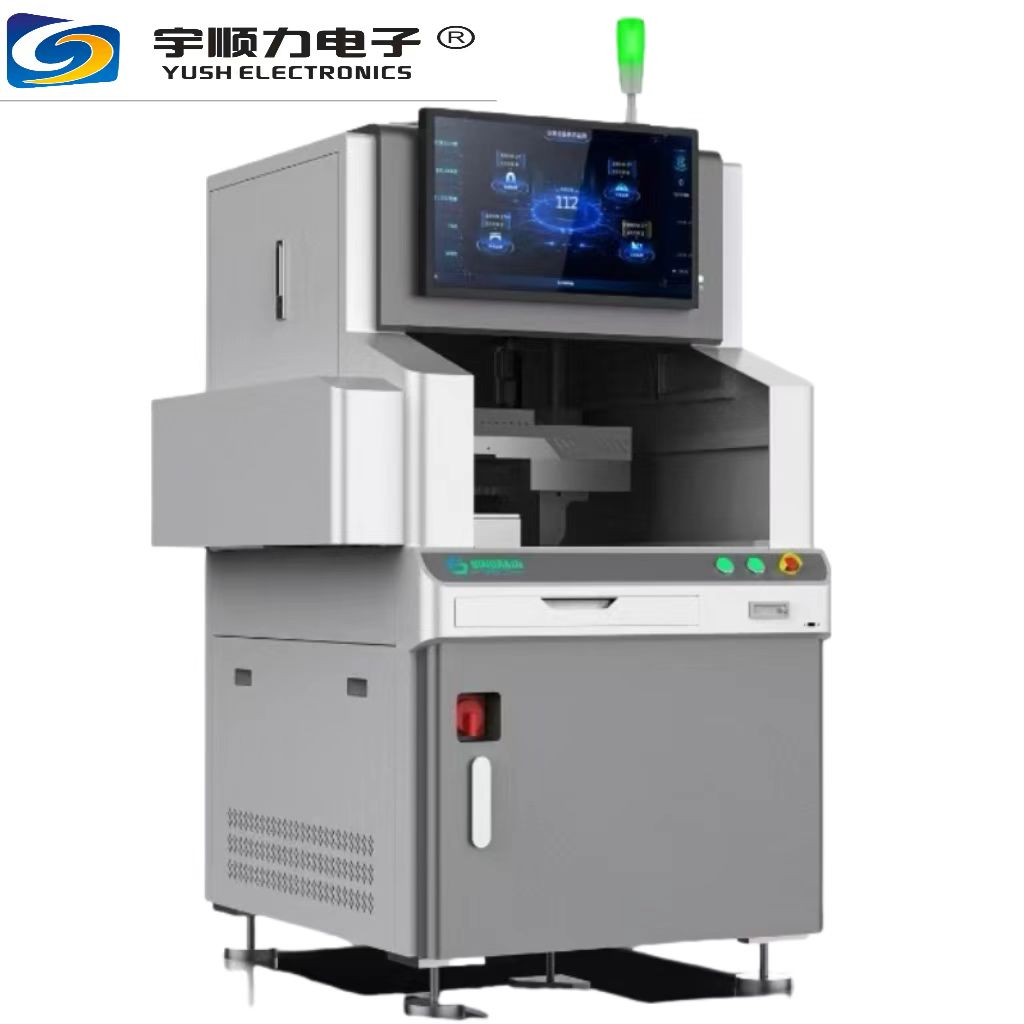

Solve the difficulties in DIP welding 1.Solve the flexible production of multiple varieties and small batches (flexible and convenient) 2.Quick online welding, no fixtures required (direct welding can be done with a safe distance) 3.Extremely low equipment purchase cost (low initial investment cost) 4.Extremely low usage and maintenance costs (saving tin slag, flux, electricity and consumables) 5.The tin penetration rate is 100% and the welding yield rate is over 98% 6.Extremely low floor area (about 1 square meter) Selective wave soldering working mode During offline selective welding,the welding nozzle is fixed. The PCB board is set according to the program. Move in the X,Y, and Z axes to achieve the soldering of PCB solder joints. Specification items

Previous Product:

Desktop Selective Wave Soldering YS-E320

Next Product:

Split Selective Sprayer YS-320F

|

||||||||||||||||||||||||||||||||

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |