|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

|

Description:

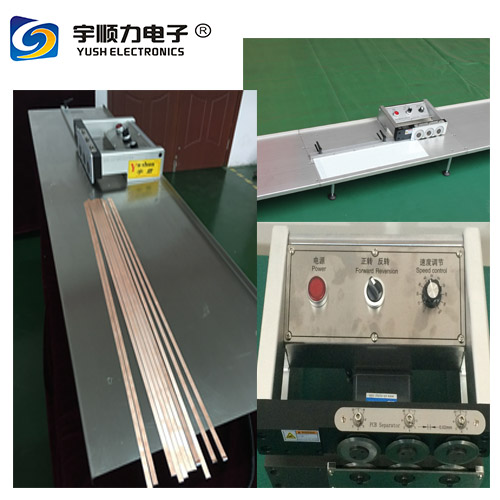

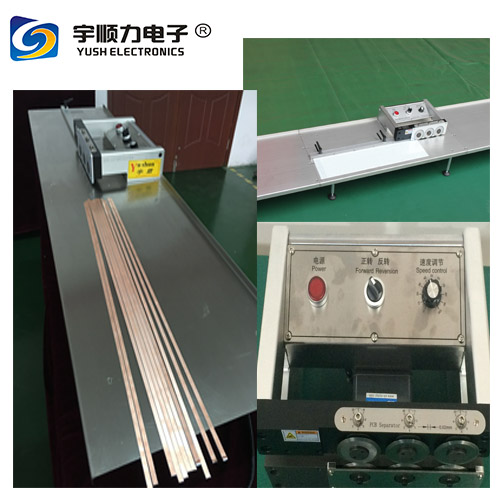

Aluminum Substrate Substrate Substrate YSVC-3S (LED Lamp Aluminum Substrate Substrate Substrate)

YSVC-3S Specification 1. Model YSVC-3S with 2.4M platform 2. Size 880 * 420 * 320 mm (L * W * H) 3. Voltage 220 V/50 HZ or 110 V 4. The minimum part distance of V-groove is 1mm 5. machine weight 52kg 6. Maximum assembly height 20 mm 7. Cutting thickness 0.6-5.0 mm 8. Cutting speed 300-500 mm/s 9. Suitable PCB length is unlimited

Product characteristics: 1. Using a unique cutting method, the circuit board is cut by six blades. It consists of an upper blade and a lower blade, and is also a cutting unit. 2. Because of many times of cutting, the cutting process is very smooth, which greatly improves the position ability of V-CUT slot. Even if there are shallow V-CUT grooves, the plate will not jump out of the blade to avoid disadvantage. 3. Because the cutting force of the blade is very small. Abd is made of high-speed steel imported from Sweden. The durability of the blade is greatly improved, and the service life of cutting aluminium sheet can be one year or longer. 4. There are three groups A, B and C. The whole cutting process is divided into three stages, from group A blade cutting 40% plate to group B blade cutting through group A slotting to complete another 40%. The final 20% cutting C group blades and finishing. Because each cutting volume is very small, the stress generated in the cutting process is reduced by more than 80% compared with the traditional cutting. Therefore, the edge and surface of the plate are very smooth without warping. At present, it is the only machine that can guarantee the deformability of aluminium sheet after cutting. 5. All cutting blades are calibrated by excitation dual-frequency laser interferometer. Ensure that the reamer can accurately continue to cut into the slot that has been cut with the rake. The jitter of the tool tip is less than 0.02mm. Ensure perfect cutting quality.

Previous Product:

PCB Separator For Automotive Electronics Industry With Two High Speed Steel Blades

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |