|

|

Items

|

Parameter

|

|

Complete

machine

|

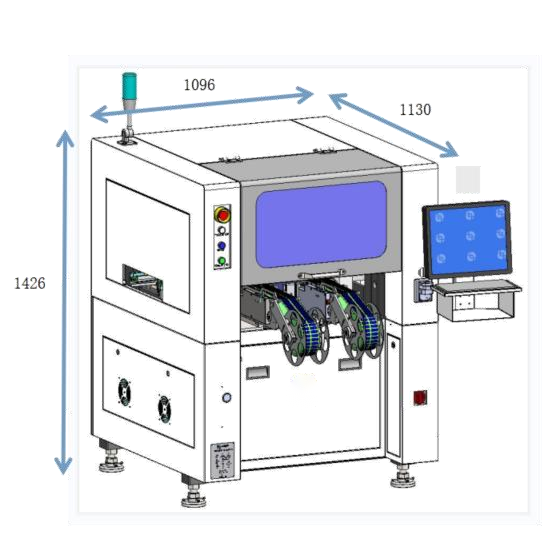

Dimension

|

About 1096 × 1130 × 1426mm

|

|

Weight

|

About 800Kg

|

|

Power Supply

|

AC220V ± 10% 50Hz

|

|

Power

|

1.0KW

|

|

Gas source

|

0.4-0.6MPa

|

|

Air Pressure

|

Less than 1L/min (air consumption of each vacuum generator 46L/min)

|

|

Mounting

|

Production

|

Max 2500pcs/h 或 1.2-2.5sec/pcs Note 1

|

|

Product/vehicle size

|

L50 ×W50-L340 ×W280mm

|

|

Product/vehicle thickness

|

1-6mm

|

|

Material frame size

|

L * W: 2 x 2-100 x 40 mm, Thickness: 0.05-0.3 mm (Special thickness can be customised, diameter over 30mm

needs to be customised.)

|

|

Material Specification

|

1-10pcs/line (roll)

|

|

Number of mounting heads

|

2 PCS

|

|

Label Feeder Capacity

|

2pcs 105mm Smart Feeder (customizable)

|

|

Entry direction

|

L-R 、R-L 、L-L 、R-R

|

|

Transfer rate

|

Max 600mm/sec

|

|

Transport Height

|

900 ±20mm

|

|

Mounting Angle

|

0-360 °

|

|

Mounting accuracy

|

±0.05mm(excluding material deviation)

|

|

Position Accuracy

|

±0.025mm

|

|

Repositioning Accuracy

|

±0.005mm

|

|

Others

|

Stripping method

|

Optical fiber detection + software control

|

|

Suction test

|

Vacuum detection 、drop mark detection

|

|

Product support mode

|

Magnetic thimble 、flexible side clamp

|

|

Track widening

|

automatic adjustment

|

|

Control Method

|

pc industrial computer

|

|

Machine connection

|

SMEMA port

|

|

Operating Environment

|

Windows

|

|

Division_Purview

|

coded lock

|

|

on-line mode

|

Reserved network interface

|

|

Human Machine Interface

|

LCD

|

|

Input Equipment

|

Keyboard 、mouse

|

|

Alarm method

|

Three-color light, buzzer, software warning popover

|