|

|

||

|

|||

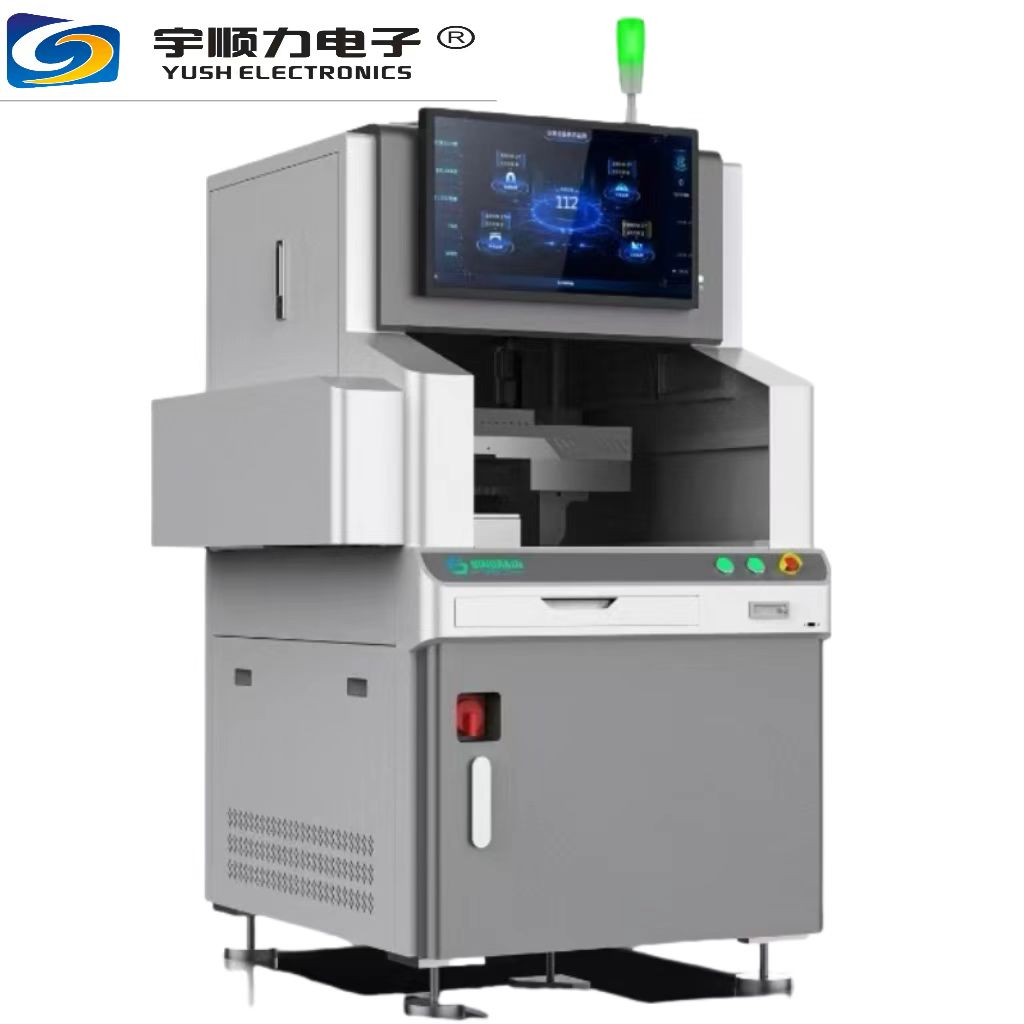

苏州市宇顺力电子有限公司 刘小姐 :+86 13416743702 曹先生:+86 13862072520 电话: 0512-62751429 传真: 0512-62751429 网址:http://www.yushunli.com http://www.smtcj.com 邮箱: sales@hk-yush.com 地址:地址:苏州昆山陆家镇金阳东路1068号国瑞创业园H栋2楼。 邮编: 215331 |

|

阿里国内站 |

| 波峰焊 | ||||||||||||||||||||||||||||

|

详细介绍:

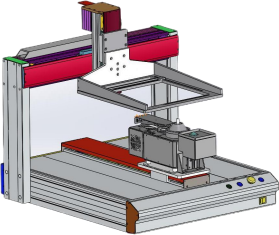

Solve the difficulties in DIP welding 1.Solve the flexible production of multiple varieties and small batches (flexible and convenient) 2.Quick online welding, no fixtures required (direct welding can be done with a safe distance) 3.Extremely low equipment purchase cost (low initial investment cost) 4.Extremely low usage and maintenance costs (saving tin slag, flux, electricity and consumables) 5.The tin penetration rate is 100% and the welding yield rate is over 98% 6.Extremely low floor area (about 1 square meter) Selective wave soldering working mode During offline selective welding,the welding nozzle is fixed. The PCB board is set according to the program. Move in the X,Y, and Z axes to achieve the soldering of PCB solder joints. Specification items

|

||||||||||||||||||||||||||||

版权所有© www.hkyush.com 苏州宇顺力电子设备制造厂 网站管理

|