|

|

||

|

|||

苏州市宇顺力电子有限公司 刘小姐 :+86 13416743702 曹先生:+86 13862072520 电话: 0512-62751429 传真: 0512-62751429 网址:http://www.yushunli.com http://www.smtcj.com 邮箱: sales@hk-yush.com 地址:地址:苏州昆山陆家镇金阳东路1068号国瑞创业园H栋2楼。 邮编: 215331 |

|

阿里国内站 |

| 钢网清洗机 | ||||||||||||||||||||||

|

机器简介:Machine description:

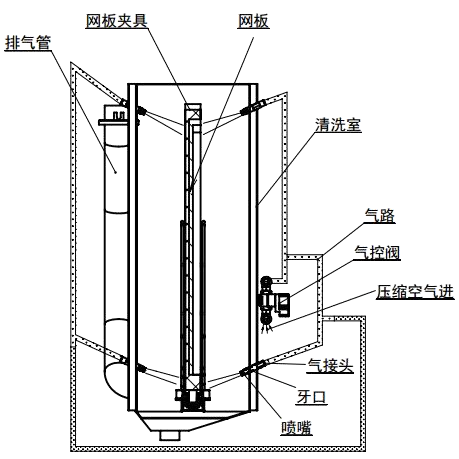

YS-210全气动PCB误印板清洗机专门用于SMT制程误印PCB,刮刀,Feeder 零部件,小批量PCBA等清洗。机器采用压缩空气为动力,采用上下喷淋清洗方式,一键式操作,自动完成清洗+干燥整个流程,特殊泵浦和渐增式喷嘴排列,产生稳定的清洗喷射力,确保高效率和高品质清洗。 YS-210 pneumatic PCB Auto Cleaning Machine is designed to clean misprint PCB solder paste, squeegee, Feeder parts, a small amount of PCBA. Driven by compressed air, the machine clean PCB from upper and lower side, by “One button” easy operation, the machine complete “clean + dry “process automatically; Special pump and paten designed rotation pod guarantee stable jet pressure to make sure efficient and high quality cleaning result. 机器特点:Machine Feature: 全不锈钢结构,美观耐用,耐酸碱溶液,设计使用寿命10年。 SUS 304 machine structure, resist Acid and Alkali corrosion, 10 years lifespan. 完全采用压缩空气为动力,不用电,无任何电火花引起的安全隐患。 Totally Driven by compressed air , no electric power, totally no fire or explosion risk caused by electrical spark . 一键式简便操作,清洗,干燥一次完成。 One button easy operation, clean and dry complete automatically 推拉式清洗篮设计,物品取放快捷,无需专门治具。 Push-pull cleaning basket, easy to put and take out cleaning parts, no need special jigs. 配备自动加液,排液功能。 Equipped auto liquid fill in and drain function 清洗溶液自动循环过滤,消耗量低。 Liquid recycle use to ensure low consumption 内锁式安全门设计,开门即停止,确保安全。 Inner-lock safety door, once open, machine stopped immediately to ensure operator safety 高达1um精密3层过滤系统,确保溶剂干净。 3-level precise filtering system to make liquid clean by recycled use 全球知名品牌部件,确保机器长期稳定使用。 Super well-known Pneumatic parts from all over the word ensure stable use of the machine 模块化设计,检修维护方便。 Modular design ensure easy maintenance 机器规格: Machine Spec:

上一个产品:

20微米钢网清洗机

下一个产品:

SMT钢网清洗机

|

||||||||||||||||||||||

版权所有© www.hkyush.com 苏州宇顺力电子设备制造厂 网站管理

|