|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

Description:

Double Platform Rotary Pulse Hot Press YSPC-1A

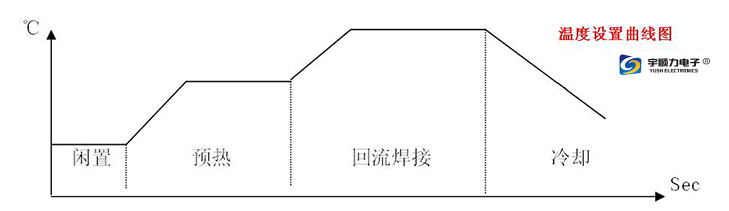

Hot press, pulse hot press YSPC-1A 1. According to different products, the heating rate can be adjusted. 2. Welding joints of special materials to ensure the average pressure of products. 3. Equipped with vacuum function, it is easier to adjust alignment. 4. Temperature numerical control, clear and precise. 5. A digital pressure gauge is available to predict the pressure range. 6. microcomputer control, accurate and stable 7. Programmable Curves Include Preheating and Reflow Temperature 8. Suitable for all kinds of high density TAB, TCP bonding and FPC, FFC and PCB solder bonding 9. Low vibration, low noise and no voltage fluctuation. 10. Molybdenum alloy is used to replace the traditional titanium alloy in the welding joint, which has the advantages of fast temperature rise and cooling, good heat transfer coefficient and corrosion resistance. 11. Single head and double fixture design, high efficiency, saving labor costs. Specification of Pulse Hot Press: (1) Machine size: 700 *800 *950mm (length/width/height) (2) Dimensions: 200 x 260 mm (3) Machine weight: 110 kg (4) Working pressure: 0.4-0.7Mpa Power supply: AC220V +10% 50HZ, 2300W Warming-up Settings: Two-stage Settings, Four Storage Procedures Working environment: 10-60 C, 40-95% Welding Pressure: 1~50Kg Temperature setting: room temperature ~500 C error (+5 C) _Hot pressing time: 1-99s _Hot pressing accuracy: 0.2mm _Size of hot pressing head: 90X5mm

Equipment Operation Description It is very important to set the above parameters accurately for welding products. A good solder joint will probably enable the solder to weld two surfaces abundantly, and to melt tin on the surface of two parts. Only by effectively cooperating with the above parameters can the good products be soldered. FPC consists of two layers of polyimide and copper platinum. FPC operates at temperatures ranging from 130 to 200 degrees. It can experience short welding temperatures up to 300 degrees. When PCB and FPC are welded, heat dissipation effect will be brought to the indenter (FPC and PCB absorb heat, and when the indenter is pressed down, heat dissipation of the indenter will be caused by convection of welding data with air around the indenter). Adding FPC between 0.02 and 0.12 thickness, the loss of 50 to 80 degrees may occur at the welding surface. Therefore, the temperature of loss should be added when setting the temperature. (Solder melting point loss temperature). Parameter values and their setting size: Firstly, the setting of heating speed gear. There are 8 gears in the heating speed gear (1 to 8 gears). One gears are heated fast and eight gears are heated slowly. Its setting is related to the width of the pressing head. Narrow heads (10mm) are heated slowly (6, 7, 8 gears) and wide heads (80mm) are heated fast (1, 2, 3 gears). Second, the setting of temperature and time: the setting of temperature is divided into three sections: preheating, welding, and cooling. 1. Preheating temperature setting in the first stage: make the solder pad tin point to the melting state. Its setting value is about the melting point temperature of tin. Lead-free is about 230 degrees. Lead is about 180 degrees. Time setting is between 2 and 4 seconds. The advantages of preheating setting are as follows: 1) It takes about a few seconds for the head temperature to rise to the welding temperature (including the setting time of holding the temperature). At this time, flux activation improves the melting tin by removing the oxide layer. Preheating generally dissipates more heat in excessive products, or when weak substrate (such as ceramics) needs to be heated in a more controlled way to avoid cracking. 2) At the second stage of heating, the tin activity of the solder pad is better and can move smoothly. Otherwise, at the second stage of heating, the pressure head suddenly rises to the melting temperature of the tin, resulting in the sudden melting of the solder on the solder pad under pressure, while the low temperature at both ends of the solder pad prevents the tin from moving forward and backward, resulting in the left and right movement and short circuit. 2. The setting of the second heating temperature: make the FPC and PCB connect completely, and the setting value depends on the welding material. Generally speaking, there is lead between 230 and 320 degrees. Lead-free is between 280 and 350 degrees. Because of the different products, the size of the indenter is different, the speed of heat dissipation is different. According to the amount of heat dissipation, the setting temperature is determined. Note: When copper deposited by electrolytic deposition of FPC is below 0.03mm, the temperature of two sections should not be set too high. Probably the temperature of complete melting of tin will be enough. If the temperature is too high, the temperature transmitted to the welding surface by FPC will be too high, resulting in strong activity of tin. Simple formation of short circuit and tin beads. And the product will change color because of high temperature. Too low a temperature will cause a snowflake short circuit. The following is a reference value: Temperature setting scale in the first section of lead-free product list: 230-280: temperature setting scale in the second section: 280-350 degrees. The temperature setting scale in the first section of the leaded products list is 200 to 230 and the temperature setting scale in the second section is 230 to 320 degrees. 3. Cooling temperature setting in the third stage. The setting is to allow the two welded surfaces to be fully cooled to condensation. Avoid indentation head after welding products, solder joints do not condensate on the rise, at this moment FPC will rise with the indentation head, forming de-soldering. If the cooling temperature is set too low, the production power will be reduced, and the temperature can be set at about 180 degrees. 3. Pressure setting Generally, the setting scale is from 0.08 to 0.14MP. Lower than this setting scale, it may cause cylinder to lift slowly, or the welding is not solid and virtual welding. If the pressure is too high, tin beads will be short-circuited easily, and FPC and PCB will be damaged by deformation.

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |