|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

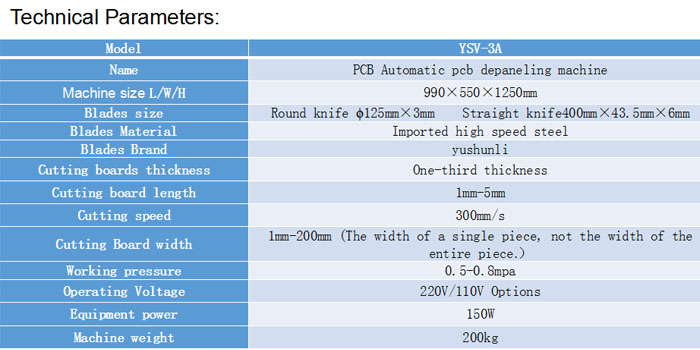

| PCB Depaneling Machine |

Description:

Product introduction:

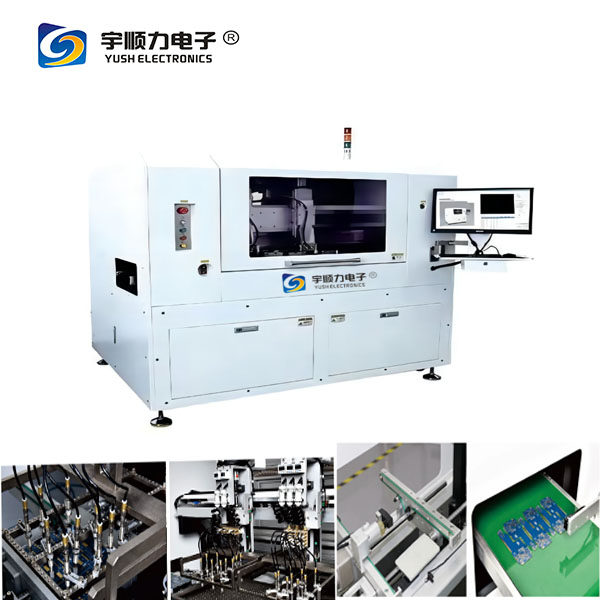

1. YSV-3A PCB automatic pcb depaneling machine, microcomputer-controlled automatic sub-board, high efficiency at the same time all kinds of advantages of the knife-type sub-board machine: stress small knife-type partition to avoid circuit board dark injury, tin Cracks and other issues, wide applicability, suitable for double-sided circuit boards with components.

Features: 1. High positioning accuracy 2. The cutting board stress is small. 3. Infrared light curtain induction, high safety performance. 4. Automatic feeding board, cutting board, more efficient. 5. The machine can be connected to the upper and lower board machine, more labor.

Previous Product:

Online boring machine, PCB boring machine, exporter

Next Product:

Dual direction automatic well type pcb splitter

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |