|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

| PCB Depaneling Machine |

|

Description:

Function and features:

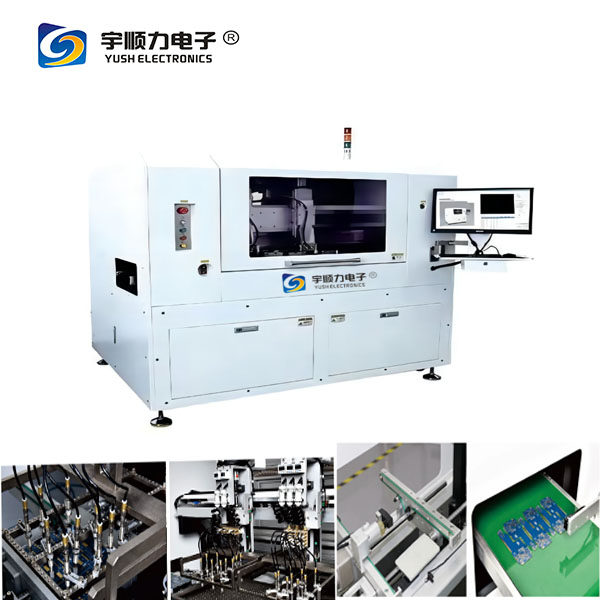

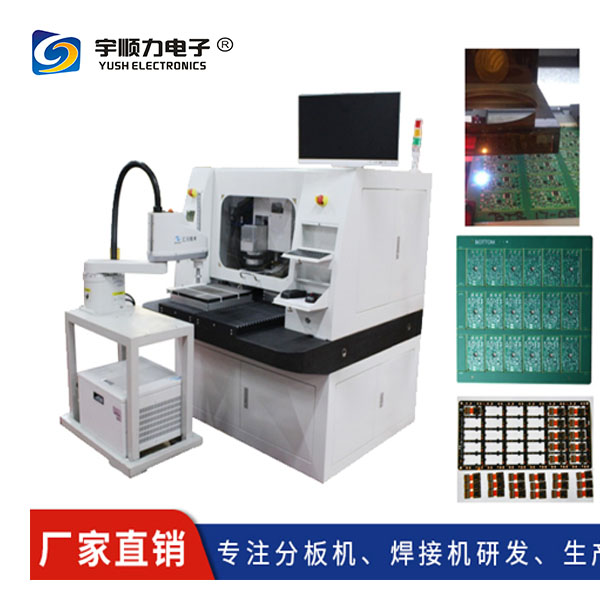

Aluminum PCB Board Depaneler Manufacture-YSV-2L

3. The straight blade moves up and down, which is available to cut double-sided board.

8. No need to feeding boards manually with high-tech device, there are reserved port for external robotic hand.

Specifications:

Cutting thickness: 0.2-3mm

Previous Product:

CNC Automatic PCB Depanelist-YSVC-650

Next Product:

SMT PCB Magazine Loader And Unloader With 4 Magazines

Related Product

|

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |