|

|

||

|

|||

YUSH Electronic Technology Co.,Ltd Contacts:Eva Liu +86 13416743702 Tel:0512-62751429 Website:http://www.hkyush.com http://www.pcbpunchingmachine.com Email:sales@hk-yush.com Address: Building H, GuoRui Pioneering Park, No. 1068 Jinyang East Road, Lujia Town, Kunshan, Suzhou. Postcode:215331 Dongguan Factory Address: 5th Floor, No.10, Shanquan Road, Yongtou Village, Chang’an Town, Dongguan City, Guangdong province, China. Postcode:523843

|

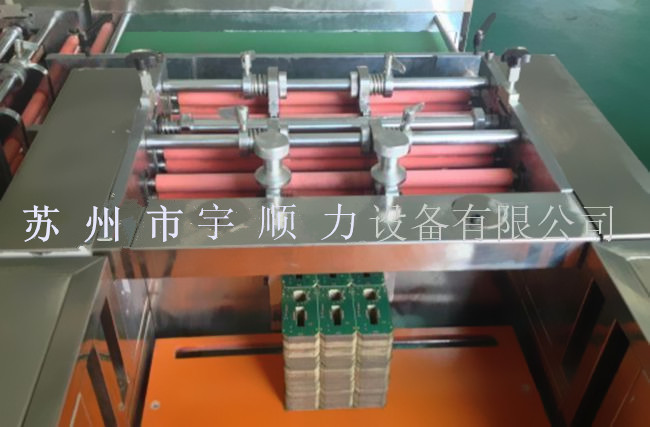

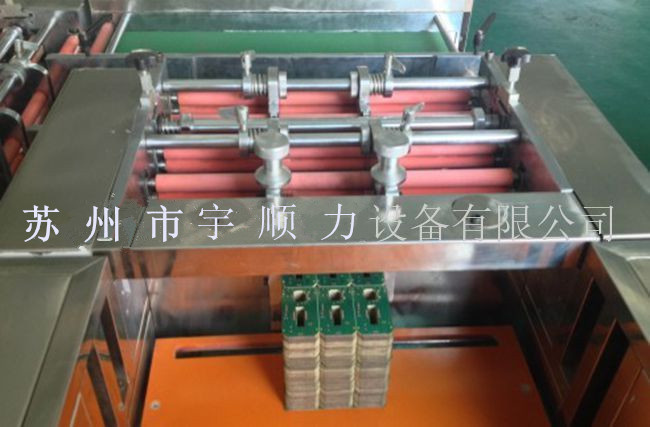

| PCB V Groove Machine | ||||||||||||||||||||||||||||||||||

|

Description:

YS-1300- PCB drilling machine

Description:

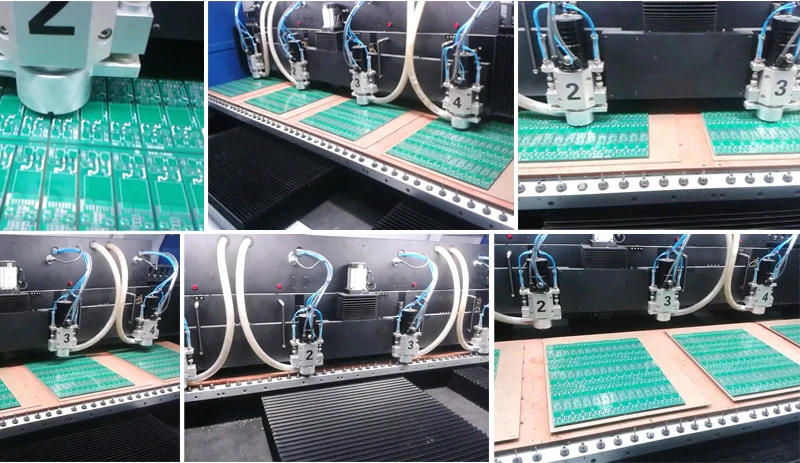

CNC routing machine. You can connect together virtually as many modules as you want forming a single line running different jobs managed from a single user interface. Each module can be configured with a different spindle type (drilling or routing) and equipped with an automatic loading and unloading system for maximum flexibility. Speed and productivity is established because of its solid structure and linear motors on all axes. Main Parameter:

Main Parameter:

standard accessories:

working Demo:

Machine Application: Application Materials: CNC PCB drilling/routing machine is good at drilling various materials: copper pcb, aluminum pcb, FR4 pcb, acrylic palte, copper plate, etc.

Previous Product:

5.5KW Most Powerful Cyclonic Vacuum Cleaner

Next Product:

Aluminum PCB Routing Machine

Related Product

|

||||||||||||||||||||||||||||||||||

Copyright © YUSH Electronic Technology Co.,Ltd All Rights Reserved. Admin *Web site related material and resources are from the Internet, if infringement please inform us, we will remove within 24 hours. |